Technical data

| Max Capacity: | 95 m³/hr |

| Max Pressure: | 16 Bar |

| Max Viscosity: | 1’000’000 cPs |

| Max Temperature: | 140ºC |

| Max Solids Passage: | 60 mm – Model & Screw Type Specific |

| Connections: | 2” – 5” (DN50 – 125) |

| Connection Types: | Hygienic Threads DIN 11851, DIN11864-1& 2, SMS 1145 Flanges acc. To EN1092 Tri-Clamp: ISO 2852 & DIN 32676 BSP & NPT Threaded Rectangular Ported Client Specific |

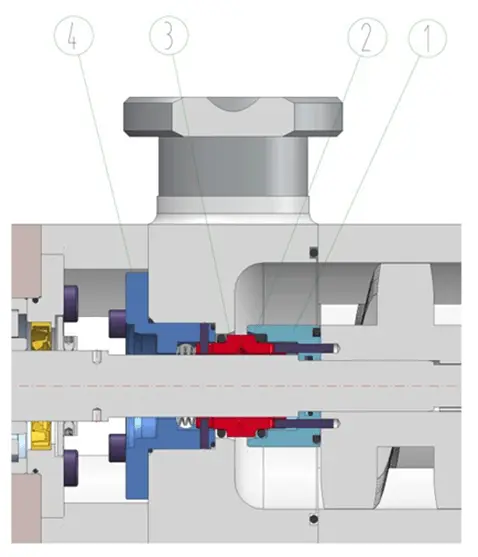

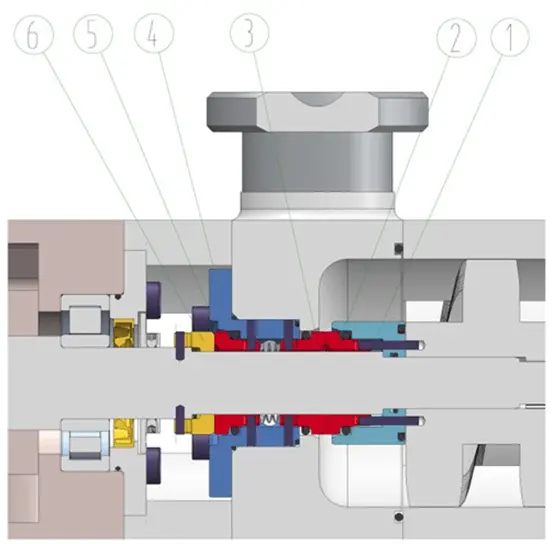

| Shaft Sealing: | Single, double quench/flush or Lip Seal |

| Sealing Materials: | SiC / SiC or Tungsten / Tungsten |

| Elastomer Materials: | EPDM, Viton, NBR, Teflon, KALREZ, e.g. according to FDA |

| Wetted Parts: | AISI 316L (AISI 316L Mo Ni or Hastelloy CX2MW N26022 upon request) |

| Surface Roughness: | ❬0.8 Micron (Std.), ❬0.5 upon request (Mechanical & Electro-Polished) |

| Hardening: | Hard Inchromizing & Plasma Nitriding (Optional) |

| Drives: | Standard: IEC, IE2, B3/B5, IP55, isol cl. F, PTC Optional: IE3, ATEX, noise reduction |

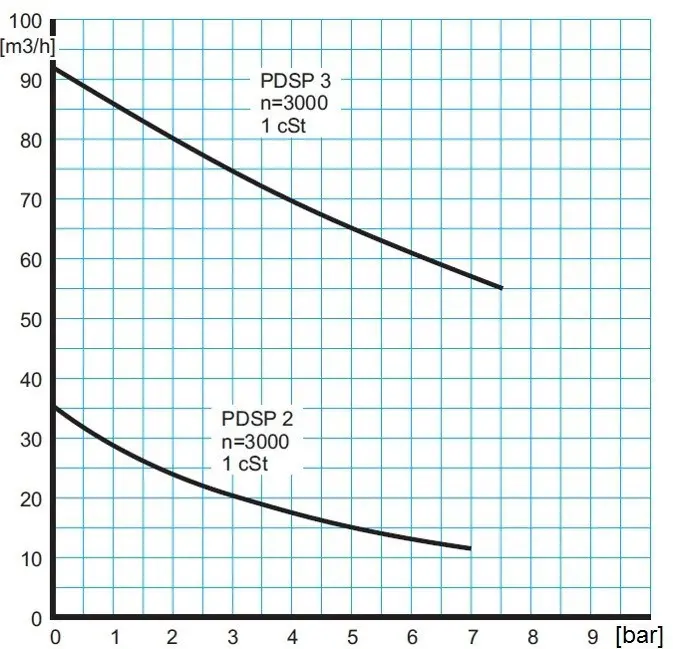

Capacity range

| Data | PDSP 2 | PDSP 3 | PDSP 4 (Coming Soon!) |

| Max Differential Pressure: | 16 Bar | 16 Bar | 16 Bar |

| Max Flow: | 40 m³/hr | 95 m³/hr | 140 m³/hr |

| Max Speed: | 3600 rpm | 3600 rpm | 3600 rpm |

| Max Temperature: | 140ºC | 140ºC | 140ºC |

| Max Viscosity: | 1’000’000 cPs | 1’000’000 cPs | 1’000’000 cPs |

| Free Passage: | 20 mm | 30 mm | 40 mm |

| NPSHr: | ❬2 m | ❬2 m | ❬2 m |

Our Screw Pump (available as a Double Screw) is Self Priming and has been produced specifically for hygienic and sanitary applications within the food, chemical and pharmaceutical industries. The Screw Pump is entirely machined from cast Stainless Steel AISI 316L with a surface roughness of ❬0.8 as standard (❬0.5 on request) to provide increased corrosion resistance. Competitors units employ a cast iron gear box with epoxy paint which can become eroded over time and need replacing/repairing. The pump shafts are constructed from Duplex Stainless Steel 1.4462 to provide extra rigidity in operation and the pump can be fitted with a number of different sealing options and elastomer materials to suit almost any application. The Double Screw Pump design is a combination of all the best advantages of Lobe, Peristaltic, Centrifugal & Circumferential Piston Pumps. The result is an incredibly versatile and robust pump which can be used for a plethora or even a combination of applications within enumerative industries. Below is a table demonstrating this:

Capacity range

| Pump type | Pomac PDSP | Twin Lobe | Circumferential Piston | Tri Lobe | Progressive Cavity |

| Hygienic | +++ | + | +- | +- | - |

| Suction capability | +++ | ++ | ++ | + | +++ |

| Pressure | +++ | +++ | +++ | + | +++ |

| Dry running | ++ | + | + | - | - |

| Gentle handling soft solids | ++ | +- | +- | ++ | ++ |

| Maintenance | +++ | +- | +- | - | - |

| Share rate | ++ | + | - | + | ++ |

| CIP Capability | +++ | +- | +- | - | - |