Specifications

| Capacity | ❮ 200 m3/hr |

| Pressure | ❮ 90 mlc |

| Impeller | Open, closed, star |

| Materials | Wetted parts: 1.4404 |

| Connections | 1,5" / DN40 to 6" / DN150 |

| Connections | Couplings: DIN11851, DIN11864-1, SMS1145 Flanges: EN1092-1, DIN11864-2, ANSI Tri-Clamps: ISO2852, DIN32676, DIN11864-3 |

| Connections | 1.5" - 6" (DN40 - 150) |

| Connection Types | Couplings: DIN11851, DIN11864-1, SMS1145, Flanges: EN1092-1, DIN11864-2, ANSI Tri-Clamps: ISO2852, DIN32676, DIN11864-3 |

| Shaft sealing | Single, double quench/flush, Inner and outer, EHEDG. according to DIN24960 |

| Sealing materials | carbonl/CrM, carbon/SiC, SiC/SiC, Tc/Tc |

| Elastomers | EPDM, Viton, NBR, Teflon, KALREZ, e.g. according to FDA |

| Surface roughness | Standard ❯ 0,8 micron |

| Motor options | Standard: IEC, IE2, B3/B5, IP55, isolcl. F, PTC Optional: IE3, ATEX, noise reduction |

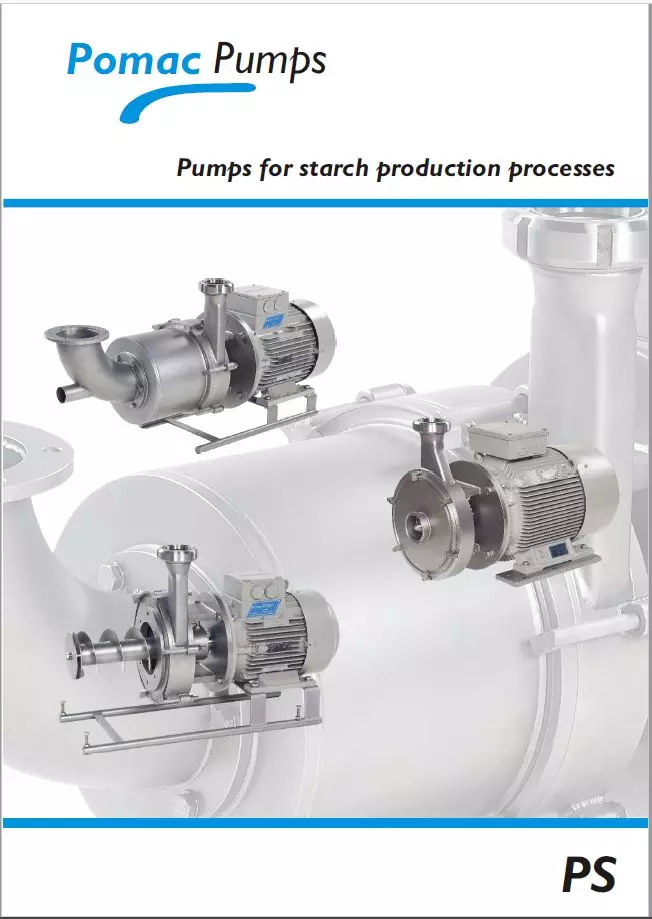

PUMPS FOR PARTIALLY DEFOAMED STARCH MILK

PSCP Pumps are specifically designed for the transfer of partially defoamed Starch Milk to hydro-cyclones within the starch production process. The principle of design is based on high efficiency, low maintenance costs and ease of assembly and disassembly, such as back pull-out of the front cover/casing. The PSCP-line is designed with narrow gaps, combined with high quality impellers this ensures very favorable efficiencies. Depending on application requirements the pump can be fitted with the following options:

- Various Impeller types

- Numerous Mechanical Seal types & material combinations

- Various O-Ring materials

- Low Surface Roughness

- Drain Connection