Technical Data

| SHAFT SEAL TYPE: | Magnetic drive |

| DESIGN: | Sub-EN 22858 - ISO 2858 |

| STANDARD: | ISO 5199 |

| CASING AND IMPELLER MATERIALS: | AISI 316 (1.4408) |

| IMPELLER TYPE: | closed |

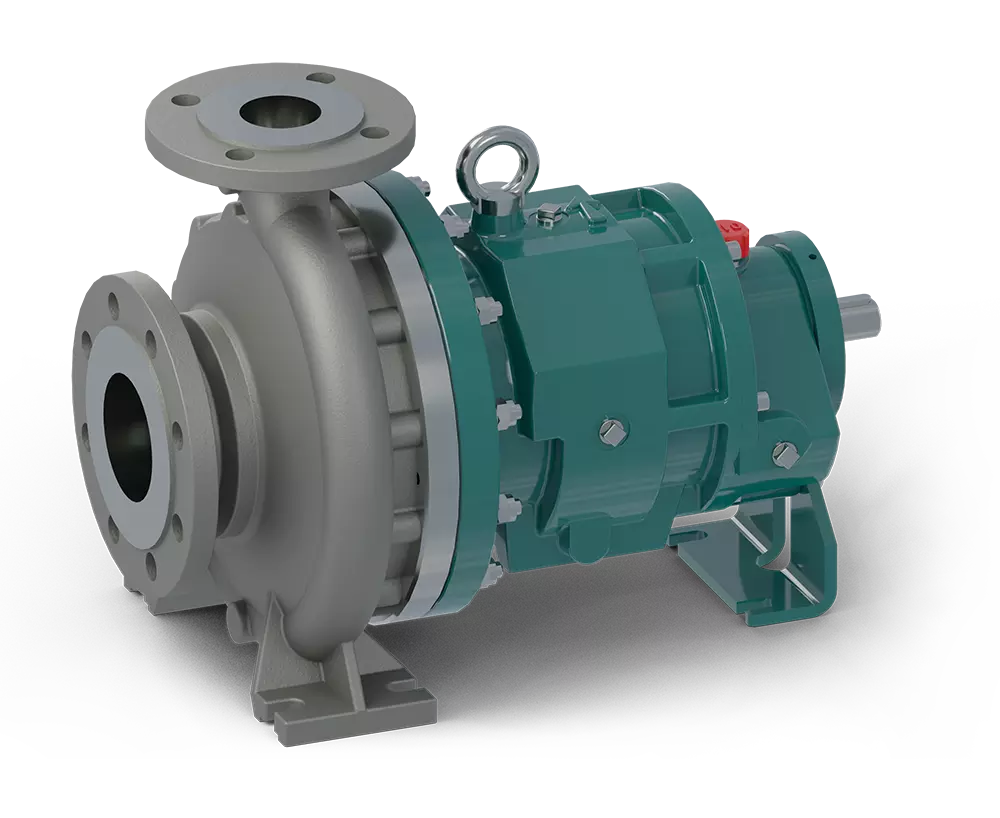

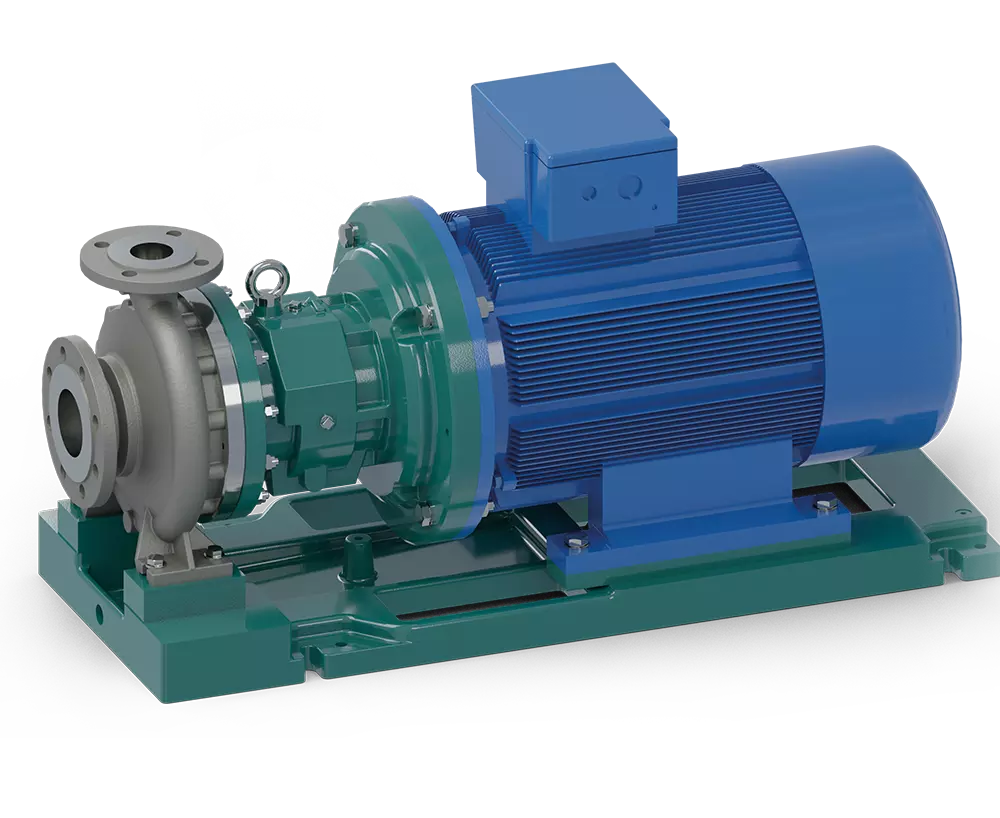

| EXECUTION: | UTS long-coupled UTS-B : close-coupled |

| MAXIMUM RATED PRESSURE @ 20°C: | PN 10 for ETS 30 e ETS 40; PN16 for ETS 50 and ETS 70 |

| FLANGES: | UNI 1092-2 (ISO 7005-2) PN16RF drilling slotted ANSI150RF |

| MAXIMUM RATED PRESSURE @ 20°C: | PN 16 |

| MAXIMUM PERMISSABLE FLUID TEMPERATURE: | -100°C/+300°C |

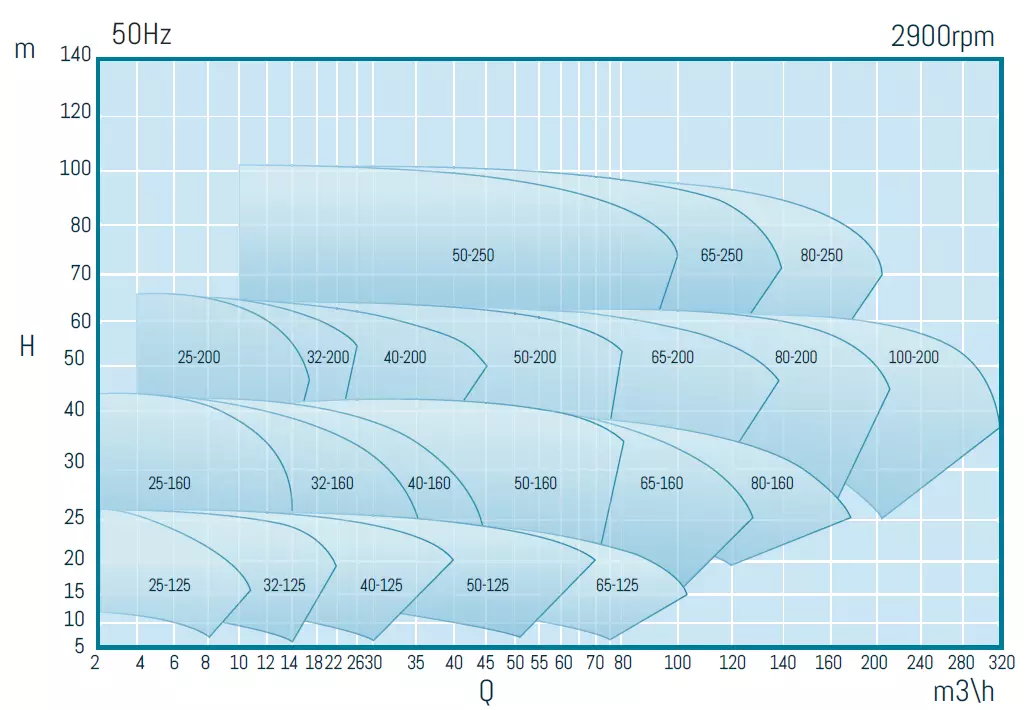

| MAXIMUM FLOW-RATE @ 2900 RPM: | 300 m3/h |

| MAXIMUM HEAD @ 2900 RPM: | 100 m |

| ALLOWABLE MEDIUM VISCOSITY RANGE: | 1 cSt - 60 cSt |

Thanks to the magnetic drive technology, the rotating motion is transmitted without any mechanical contact, simply by exploiting the attraction of the magnetic fields. Without any joint or sealing, it is achieved a complete liquid containment, eliminating risks of dangerous leakages: the safest system for the operator, as well the most respectful for the environment.

EVOlution phase two: we are proud to make a further step beyond and introduce you the new UTS EVO.

FEATURES

Metallic Magnetic drive Horizontal - Single Stage - Process Centrifugal pumps

Materials: AISI 316 (1.4408)

Long Coupled (UTS) and Close Coupled (UTS-B) execution

Versatility: suitable for handling aggressive, toxic and hazardous liquids (low viscosity, clean or slightly contaminated) in the chemical, petrochemical and pharmaceutical industries, where the need of high safety standards is the first requirement.

Reliability: the UTS are made by stainless steel.

AISI 316: on bare shaft execution, the pump is also equipped as a standard with reliable oil lubricated bearing bracket, especially developed to be suitable even under heavy duty service.

Design: UTS range shares the same hydraulic design with the UCS series (mechanical seal pumps) which have been developed focusing on Industry’s requests.

Typical applications

- Distillation processes

- Raw chemical processes. Operation h24

- Fine chemistry processes

- Thermoregulation

- Tank loading / Unloading

- Pharma-Chemical Industries