Dimensions

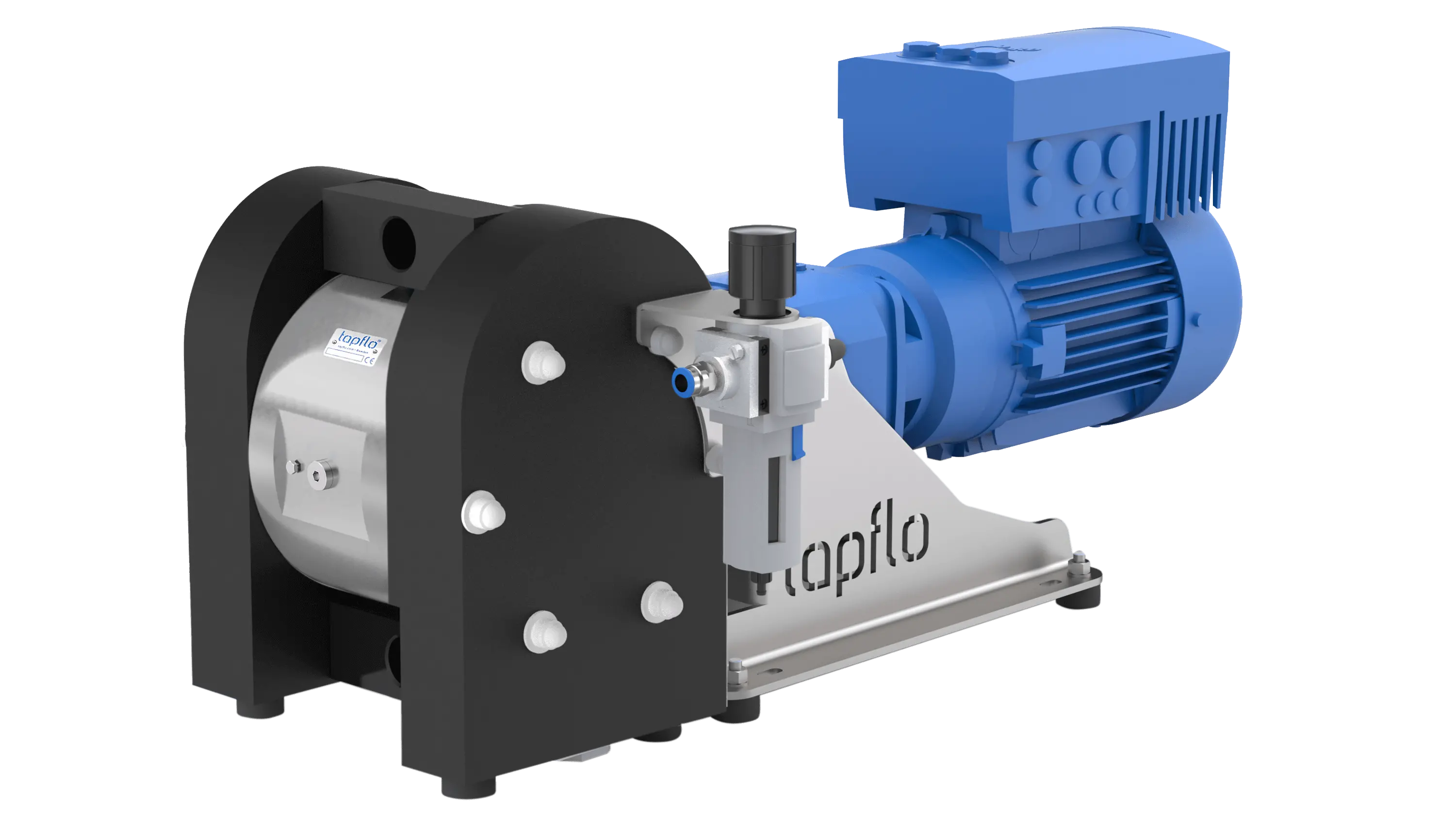

| PE & PTFE | Max capacity (l/min) |

Connections BSP inv. |

| TE50P | 48 | 1/2" |

| TE100P | 110 | 1" |

| TE200P | 220 | 1 1/2" |

| TE50T | 48 | 1/2" |

| TE100T | 110 | 1" |

| TE200T | 220 | 1 1/2" |

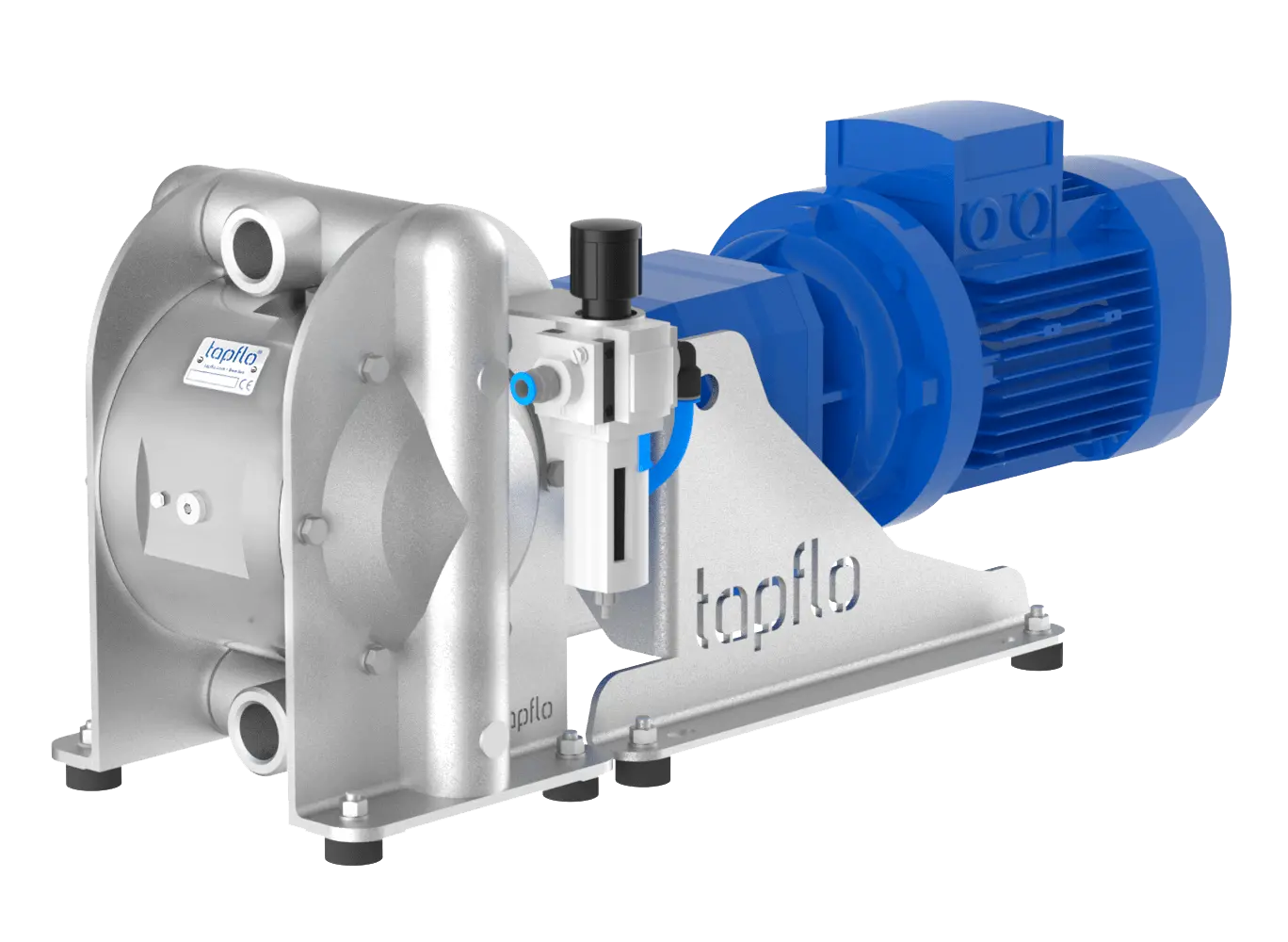

| Metal | Max capacity (l/min) |

Connections BSP inv. |

| TE70S | 48 | 3/4" |

| TE120S | 110 | 1" |

| TE220S | 220 | 1 1/2" |

| TE70A/C | 48 | 3/4" |

| TE120A/C | 110 | 1" |

| TE220A/C | 220 | 1 1/2" |

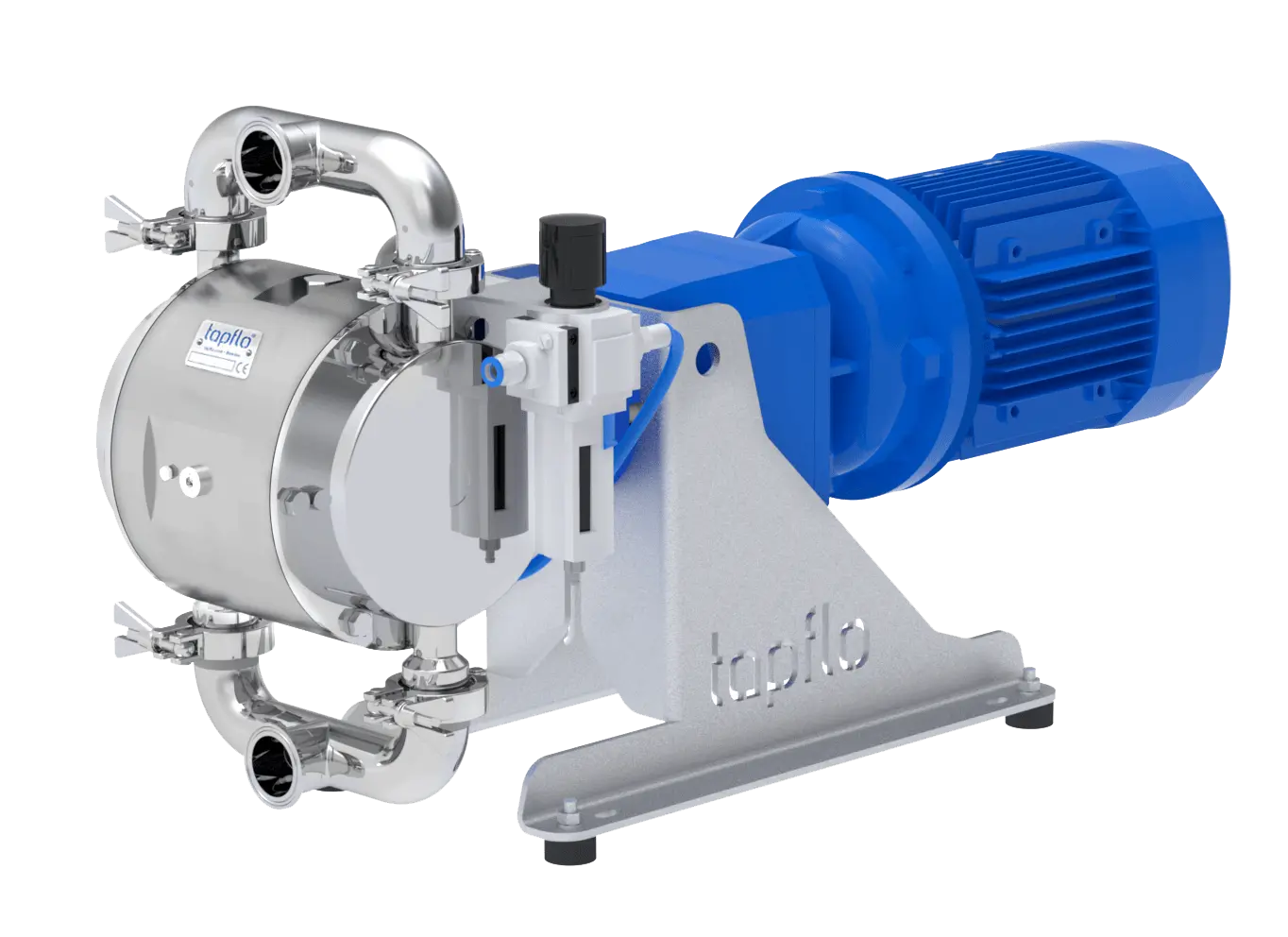

| Sanitary | Max capacity (l/min) |

Connections standard |

| TE80 | 48 | DN 25 SMS 3017 tri-clamp |

| TE125 | 110 | DN 38 SMS 3017 tri-clamp |

| TE225 | 220 | DN 51 SMS 3017 tri-clamp |

Materials of wetted parts: Aluminium, PTFE coated aluminium, Stainless steel (industrial and hygienic), Plastic (PE & PTFE)

Diaphragm and ball materials: PTFE, TFM modified PTFE, EPDM, NBR, FKM Up to 220 l/min Up to 4 bar

Options: Pressure switch, Built-on frequency inverter.

Typical applications

- Chemical industry

- Surface conditioning

- Water treatment

- Paint, print industry

- Pulp and paper industry

- Hygienic applications

- Mechanical industry

- Varnish industry

Features & Benefits

- Low energy cost. Electricity cost < compressed air cost, high efficient (IE3 class) drive

- Long diaphragm lifetime. Pneumatic and mechanical support of the diaphragm

- Run dry without damage. Easy to use, no need of guarding device

- Low spare parts cost. Pump has almost identical design of the wetted side as standard Tapflo air operated diaphragm pump therefore many spare parts are the same

- Self-priming from dry suction pipe. More options of installation

- Clean & easy maintenance. No hydraulic fluid required, no danger of leakage

- Few components & long life design. Low downtime and maintenance cost