Wide range of centrifugal pumps in stainless steel, and in plastics PP and PVDF. Horizontal pumps, magdrive pumps and vertical pumps. Tapflo Centrifugal pumps are some of the most versatile pumps on the market today. They can be used in a variety of installations in numerous applications. Thanks to the simple operating principle, with a compact and reliable design. The pump range has a very wide range of applications – from transfer of water, to pumping of chemicals.

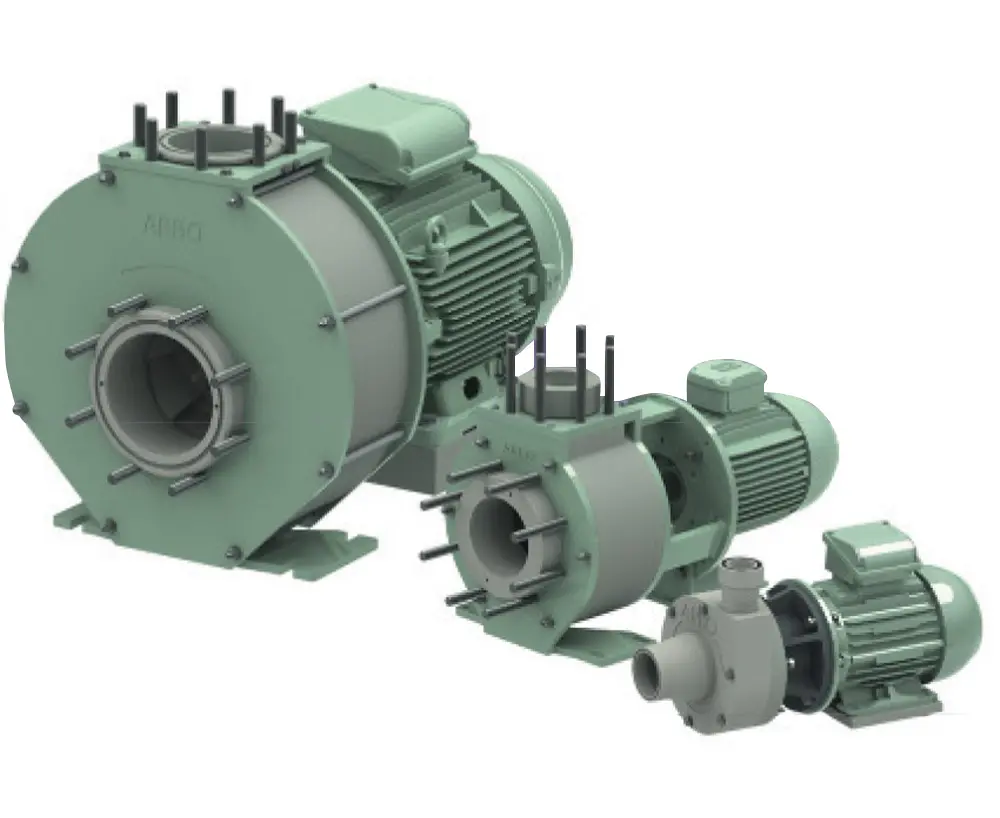

CTX high performance pumps

Tapflo's premium pump series delivers superior performance. Compact, reliable and robust, CTX centrifugal high-performance pumps assure long-term failure-free operation, resulting in minimal downtime.

CTXS - self-priming high performance pumps

Thanks to its self-priming capability, the pump can be used in situations where a dry suction lift is necessary. As the standard CTX pump is not capable of generating negative pressure, by a simple modification, we can allow the pump to lift the liquid from up to 5 m.

CTI industrial pumps

There are two types of CT pumps: open impeller and semi-open impeller single stage centrifugal pumps. A high quality and mechanically strong material - AISI 316L stainless steel - is used in the manufacture of these products. The pump range is designed to meet the needs of a variety of industries today.

CTH hygienic pumps

There are two types of CT pumps: open impeller and semi-open impeller single stage centrifugal pumps. A high quality and mechanically strong material - AISI 316L stainless steel - is used in the manufacture of these products. The pump range meets the needs of a wide range of industries in today's world.

CTM Magnetic drive pumps

CTM pumps are used in most industries where liquids are pumped. The pumps handle many types of low and normal viscous clean liquids such as chemical aggressive and toxic.

CTV Vertical Pumps

CTV is a single stage vertical centrifugal pump that is simple but very reliable in duty. The pump is specialized for transfer and circulation of various liquids from containers, sumps and tanks.

CTS self-priming pumps

CTS is an open impeller self-priming centrifugal pump, manufactured from AISI 316L stainless steel.The self-priming feature allows to use the pump in applications where standard CT pumps do not prove useful.

CTP Plastic pumps

The CTP pumps are semi open single stage centrifugal pumps. Since there are no metal parts on the liquid side, the pumps are ideal for chemicals transfer and circulation in surface treatment industries.

KGE

The KGE is a self-priming centrifugal pump with radial (semi-open or closed) impeller, overhung mounted on a bearing pedestal.

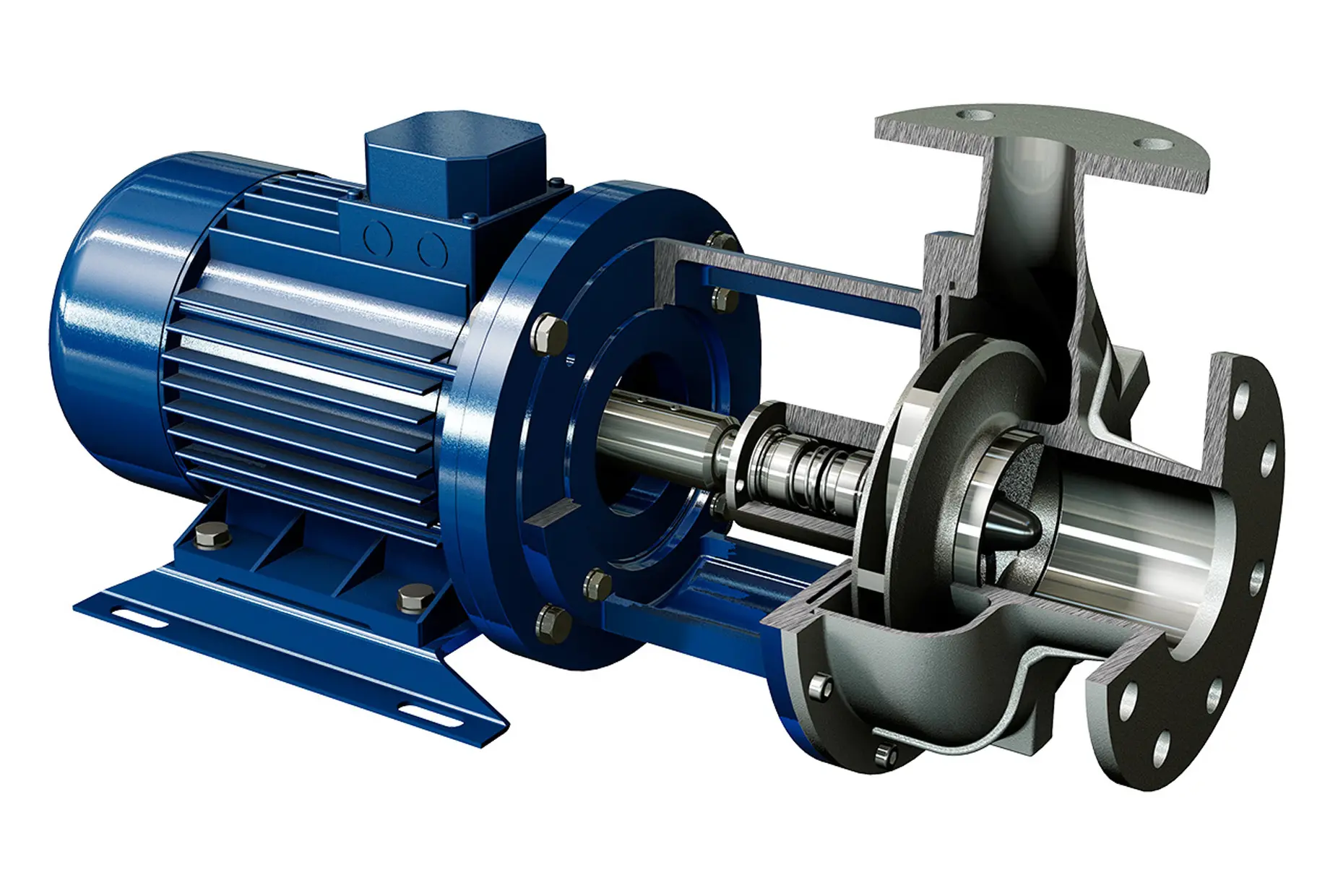

RD Closed Impeller

High hydraulic efficiencies and low NPSH requirements (investment casting impellers). Centrifugal pumps build according to ISO 2858/ISO 5199 norms.

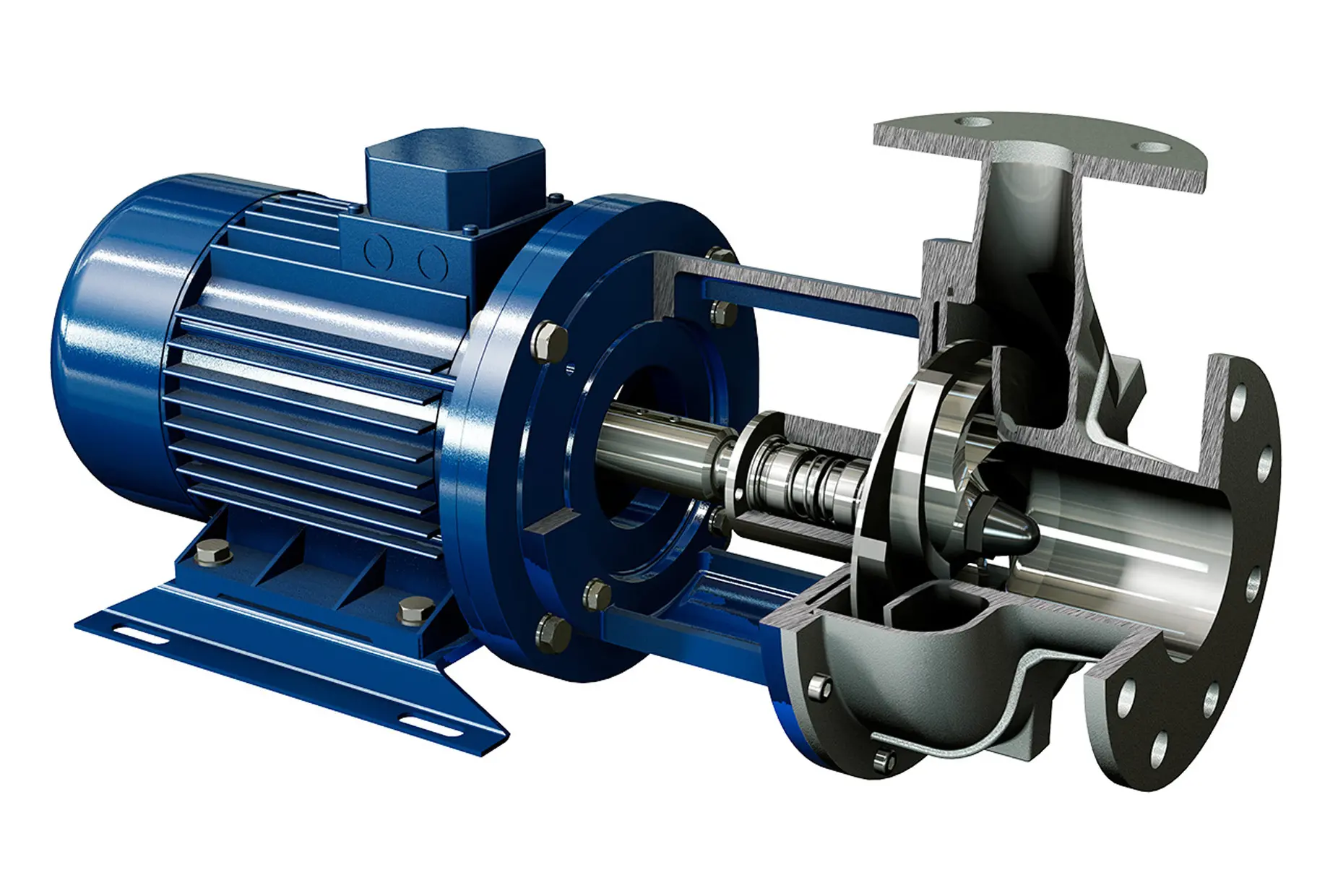

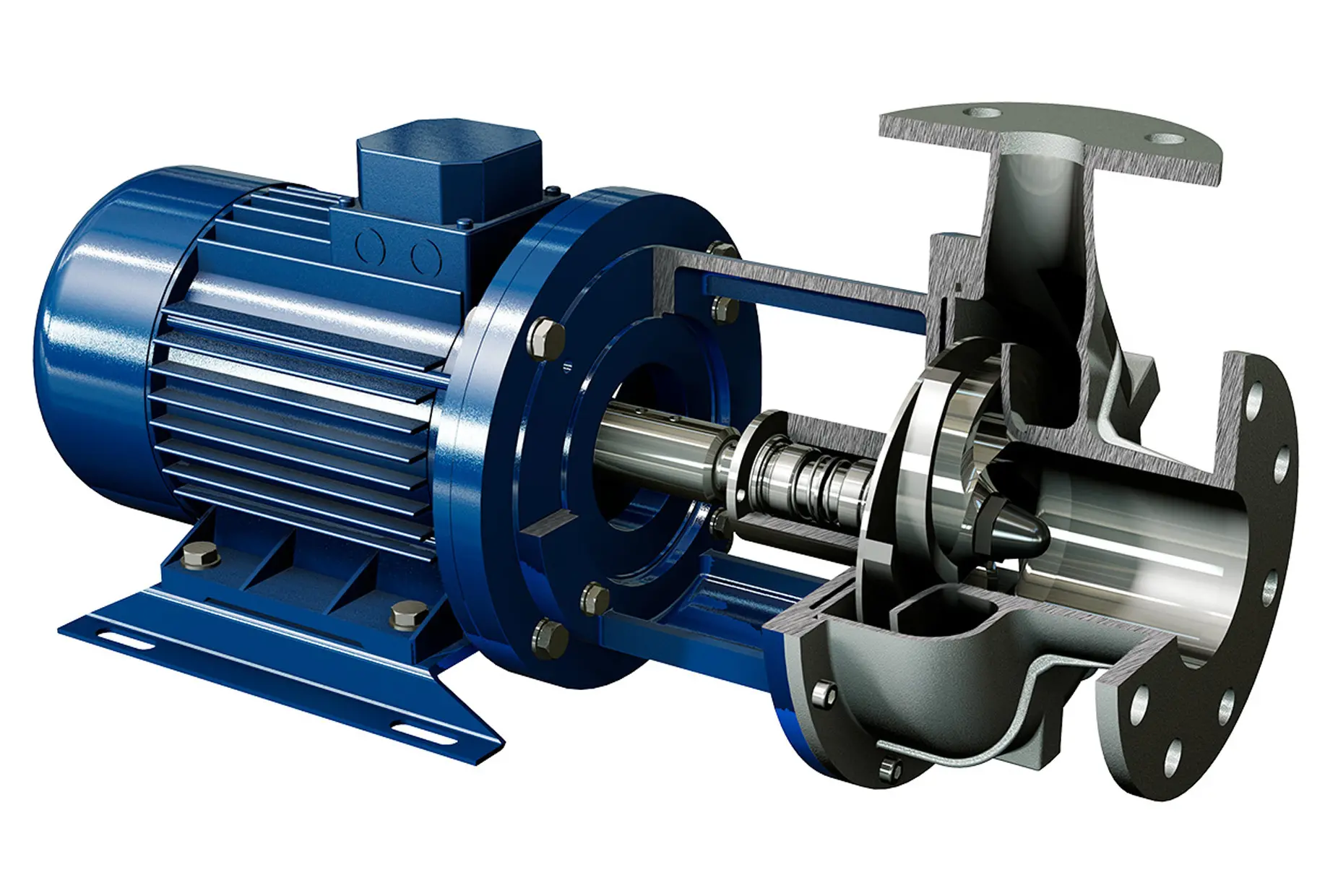

RG Semi-Open Impeller

High hydraulic efficiencies and low NPSH requirements (investment casting impellers). Centrifugal pumps build according to ISO 2858/ISO 5199 norms.

RB Channel Impeller

Impeller with special blades geometry for low NPSH and high free passage. Centrifugal pumps with bearing bracket in according to ISO 2858/ISO 5199 norms.

RC Vortex Impeller

Large free passage clearance up to 180 mm due to the completely recessed impeller. Centrifugal pumps with bearing bracket in according to ISO 2858/ISO 5199 norms.

Vertical

Closed, open, channel and vortex impeller. Vertical immersible sump pump (ISO 5199 norms) line-shaft with bearing bushes.

Cantilever

Vortex and channel impeller. Vertical cantilever sump pumps with non-clogging vortex and channel impeller.

HD CLOSED IMPELLER

Heavy duty close coupled centrifugal pumps. Same interaxis of ISO 5199 chemical norm pump.

HG SEMI-OPEN IMPELLER

Heavy duty monoblock centrifugal pumps. Same interaxis of ISO 5199 chemical norm pump.

RS VORTEX IMPELLER

Heavy duty monoblock centrifugal pumps. Same interaxis of ISO 5199 chemical norm pump.

CPC SANITARY CENTRIFUGAL PUMP

The CPC Series of Centrifugal Pumps is designed specifically for use within the Food and Pharmaceutical industries with a heavy emphasis on robust design, optimal cleanability, efficiency, low maintenance costs and simple maintenance.

CPC-ZA SANITARY SELF PRIMING CENTRIFUGAL PUMP

The CPC-ZA Series is the Self Priming variant of the CPC series. Due to its self priming capabilities, it makes it ideally suited for pumping liquids with entrained air and gases and where suction lift is required such as CIP return or Truck Unloading.

SP-LR SANITARY SELF PRIMING LIQUID RING PUMP

The SP-LR Sanitary Self Priming Liquid Ring Pump has been produced specifically for hygienic and sanitary applications within the food, chemical and pharmaceutical industries for liquids which contain air or gases.

PSCP PUMPS FOR PARTIALLY DEFOAMED STARCH MILK

PSCP Pumps are specifically designed for the transfer of partially defoamed Starch Milk to hydro-cyclones within the starch production process.

PSVP PUMPS FOR FOAMING SLURRIES

WHAT ARE PSVP PUMPS FOR FOAMING SLURRIES FOR? PSVP Pumps are specifically designed for pumping foaming slurries in the starch production process.

PSSP PUMPS FOR FIBROUS SLURRIES

PSSP Pumps for Fibrous Slurries are specifically designed for pumping fibrous slurries in the starch production process.

CP-AGF

The Pomac CP-AGF program comprises a range of stainless steel pumps, suited to pump potatoes, vegetables and fruits, without damaging them.

CP-IGH

The Pomac hygienic truck pumps range comprises a series of special versions of CP, CP/ZA and ZA stainless steel hygienic pumps, the IP impeller pump and the PLP lobe pump, all suited for mounting in trucks.

ZA-IGH

The Pomac hygienic truck pumps range comprises a series of special versions of CP, CP/ZA and ZA stainless steel hygienic pumps, the IP impeller pump and the PLP lobe pump, all suited for mounting in trucks.

CP-ZA IGH

The Pomac hygienic truck pumps range comprises a series of special versions of CP, CP/ZA and ZA stainless steel hygienic pumps, the IP impeller pump and the PLP lobe pump, all suited for mounting in trucks.

CombiTherm

CombiTherm ensures uniform process temperatures while keeping damaging heat away from seal faces and bearings. CombiTherm is designed to require no external cooling when working within the given parameters.

FRE

FreFlow pumps are self-priming centrifugal pumps suitable for handling contaminated and low-viscosity liquids. Its innovative design, eliminating the need for a non-return valve, results in less maintenance.

SealPro

This series is close-coupled. The pump is mounted directly to the motor flange by means of a plastic bracket. This compact execution is perfectly suited as stationary centrifugal pump or for use in machines.

KR/TK-HD

Again this series is close-coupled, but the bracket is made of metal for maximum stability. This compact execution, thanks to a reduced number of wear parts compared with conventional long-coupled pumps, requires less maintenance and related expenses.

TK

This configuration consists of a bare shaft pump, fully assembled with a standard motor and flexible coupling on a normalized glass fiberreinforced polyester base plate according DIN 24.259.

SumPro

This series is close-coupled; the motor is mounted directly to the pump flange by means of a plastic bracket. The pump shaft is an extended motor shaft for perfect alignment and the highest stability.

BB

This pump offers the same advantages as the previous models but is designed for ‘out of tank’ use. Main advantage is that it can be used if there is insufficient space inside the tank.

FAQ

What is a centrifugal pump?

A centrifugal pump is a mechanical device that uses a rotating impeller to create flow inside the pump volute thus increasing pressure of the fluid, typically used for transferring liquids in various industries.

How does a centrifugal pump work?

Centrifugal pumps work on the principle of converting mechanical energy from the impeller's rotation into kinetic energy and then into potential energy to move the fluid through the pump and into the discharge pipe.

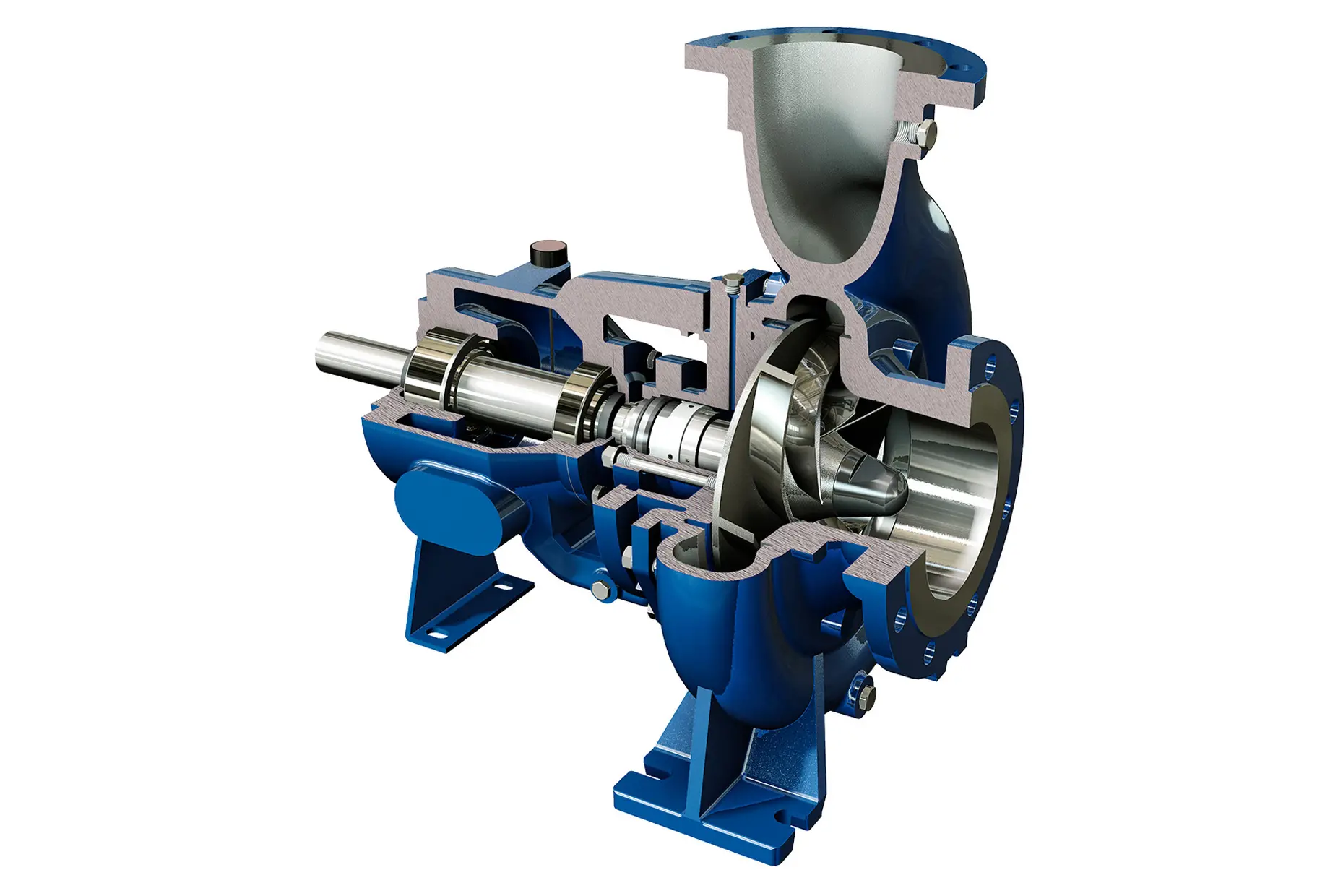

What are the main components of a centrifugal pump?

The main components of a centrifugal pump include the impeller, casing, suction and discharge ports, shaft, bearings, and mechanical seals.

What are the different types of centrifugal pumps?

Centrifugal pumps can be categorized into various types based on their design, such as hygienic pumps, industrial pumps, vertical pumps, magnetic pumps, self-priming pumps, and plastic pumps, each serving specific applications.

What are the advantages of using centrifugal pumps?

Centrifugal pumps offer high efficiency, easy installation, low maintenance, and the ability to handle large flow rates within reasonable pump sizing, making them popular for a wide range of fluid transfer applications.

Are centrifugal pumps self-priming?

Not all centrifugal pumps are self-priming. Self-priming centrifugal pumps have a unique design that allows them to draw fluid into the pump without the need for external priming.

Can centrifugal pumps handle abrasive fluids?

Centrifugal pumps are generally not well-suited for handling abrasive fluids as the impeller and casing may wear quickly. For abrasive applications, specialized pumps like slurry pumps are more suitable. It is also advisable to run the pump at lower rpm to decrease the negative effect of the abrasive liquid on the pump components.

How do I choose the right centrifugal pump for my application?

When selecting a centrifugal pump, consider factors such as flow rate, head, fluid properties, temperature, and compatibility with the application to ensure optimal performance.

How can I maintain a centrifugal pump for maximum efficiency?

Regular maintenance, including inspection and cleaning is essential to ensure longevity and efficiency. Follow the manufacturer's maintenance guidelines and schedule.

Can a centrifugal pump handle high-viscosity fluids?

Centrifugal pumps are generally more suitable for low to medium viscosity fluids. For high-viscosity fluids, positive displacement pumps like hose pumps or screw pumps are often preferred.