Technical Data

| SHAFT SEAL TYPE: | Magnetic drive |

| DESIGN: | Sub-EN 22858 - ISO 2858 |

| CASING AND IMPELLER MATERIALS: | PP lined - ETFE lined |

| IMPELLER TYPE: | closed |

| EXECUTION: | close-coupled |

| FLANGES: | UNI 1092-2 (ISO 7005-2) PN16RF drilling slotted ANSI150RF drilling slotted ANSI150RF |

| MAXIMUM RATED PRESSURE @ 20°C: | PN 10 |

| MAXIMUM PERMISSABLE FLUID TEMPERATURE: | PP: 0°C/+65°C ETFE: -15°C/+95°C |

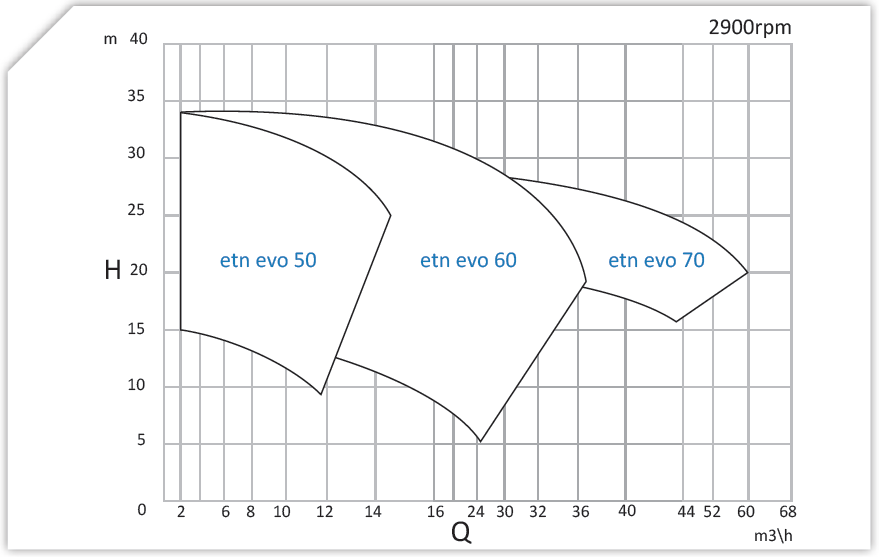

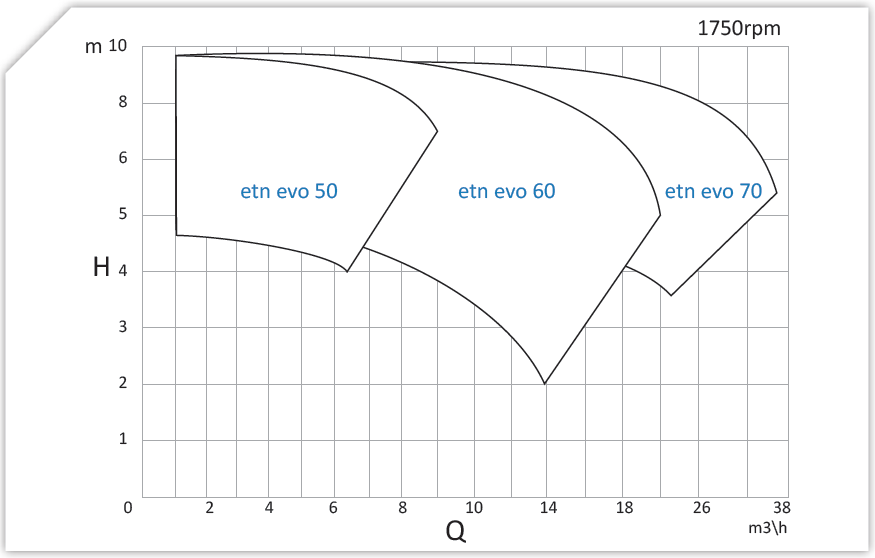

| MAXIMUM FLOW-RATE @ 2900 RPM: | 56 m3/h |

| MAXIMUM HEAD @ 2900 RPM: | 35 m |

| ALLOWABLE MEDIUM VISCOSITY RANGE: | 1 cSt - 60 cSt |

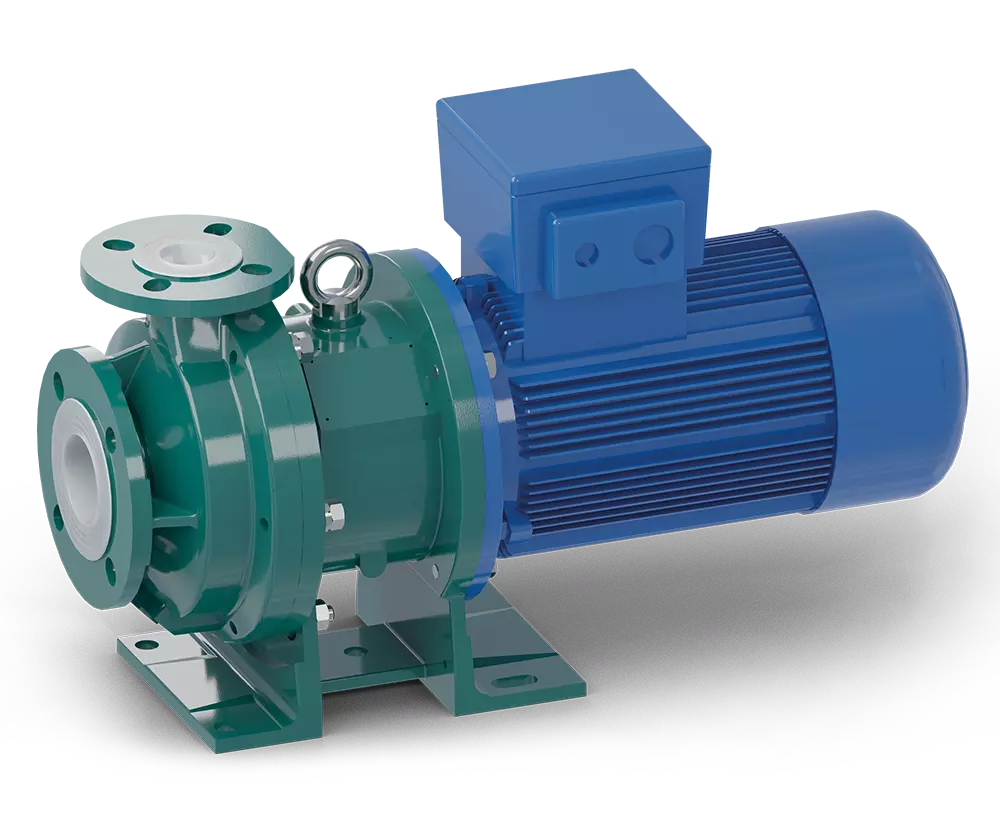

Plastic Lined Magnetic Drive Centrifugal Pumps

Plastic and Fluoroplastic Lined Magnetic drive Horizontal Centrifugal pumps Sub-ISO designed.

Lining: PP (Polypropylene), ETFE (Ethylene tetrafluoroethylene)

Close-coupled execution

Mag drive concept

The synchronous drive configuration is based on an outer magnet ring assembly built to magnetically couple with an inner magnet ring assembly.

These two magnet rings are locked together by the flux of attracting magnet poles flowing th ough the containment isolation shell.

Versatility: in the ETN EVO offers a wide range of materials for the wetted parts:

- PP (Polypropylene)

- ETFE (Ethylene tetrafluoroethylene)

Reliability: New internal circualtion path for top reliability, even under stress conditions

Design: Made with a reliable quality as the UTN, but designed for smaller applications (low duty)

Typical applications

- Basic chemical

- Fine chemical batch processing

- Waste water treatment

- Air treatment scrubber

- Tank loading

- CIP