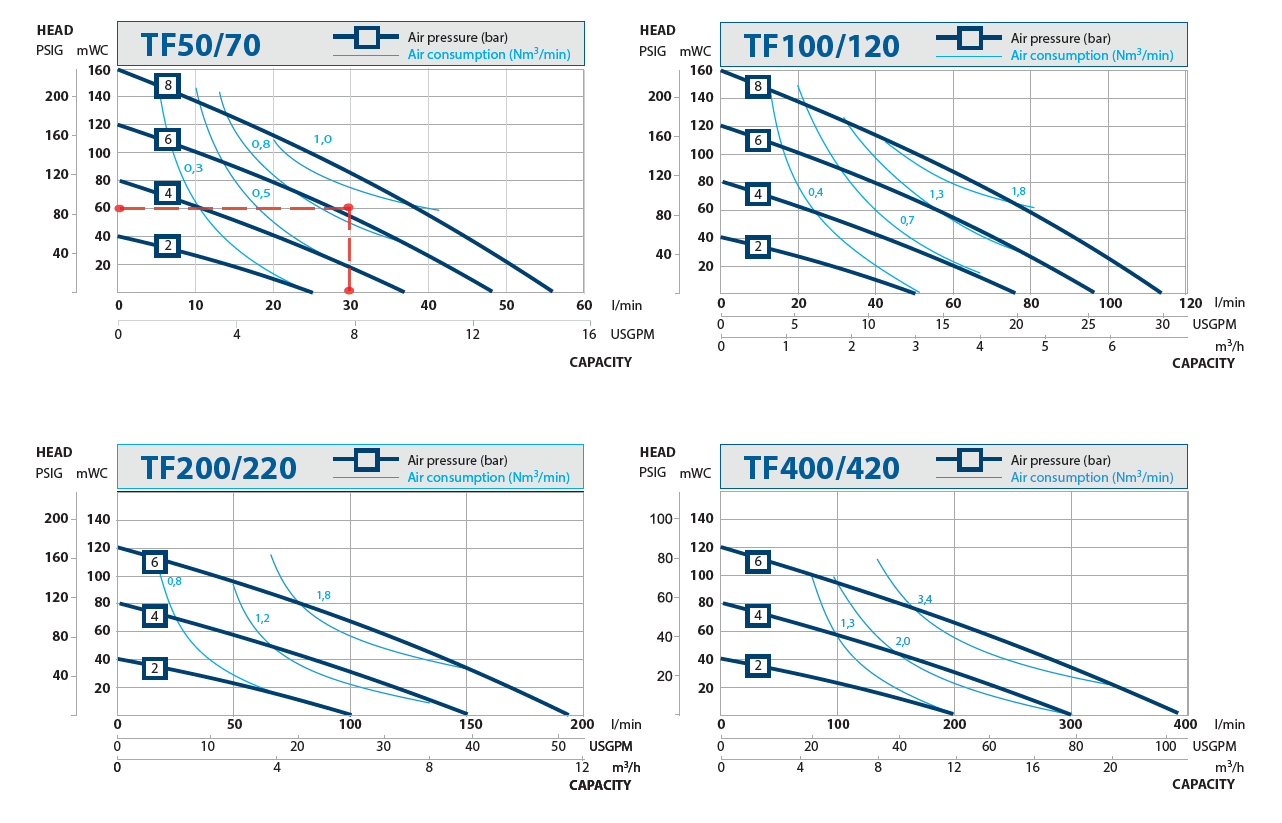

Technical data

| Pump size | Connections BSP or NPT |

*Max capacity (l/min)/(US GPM) |

| TF50 | TF70 | 1/2" | 3/4" | *60 / 15.8 | 78 / 20 |

| TF100 | TF120 | 1" | *125 / 33 | 158 / 41 |

| TF220 | TF420 | 1 1/2" | 2" | *330 / 87 | 570 / 150 |

| TF200 | TF400 | 1 1/2" | 2" | *330 / 87 | 570 / 150 |

* = This max flow is obtained when using a bypass round the pressure booster at low pressure

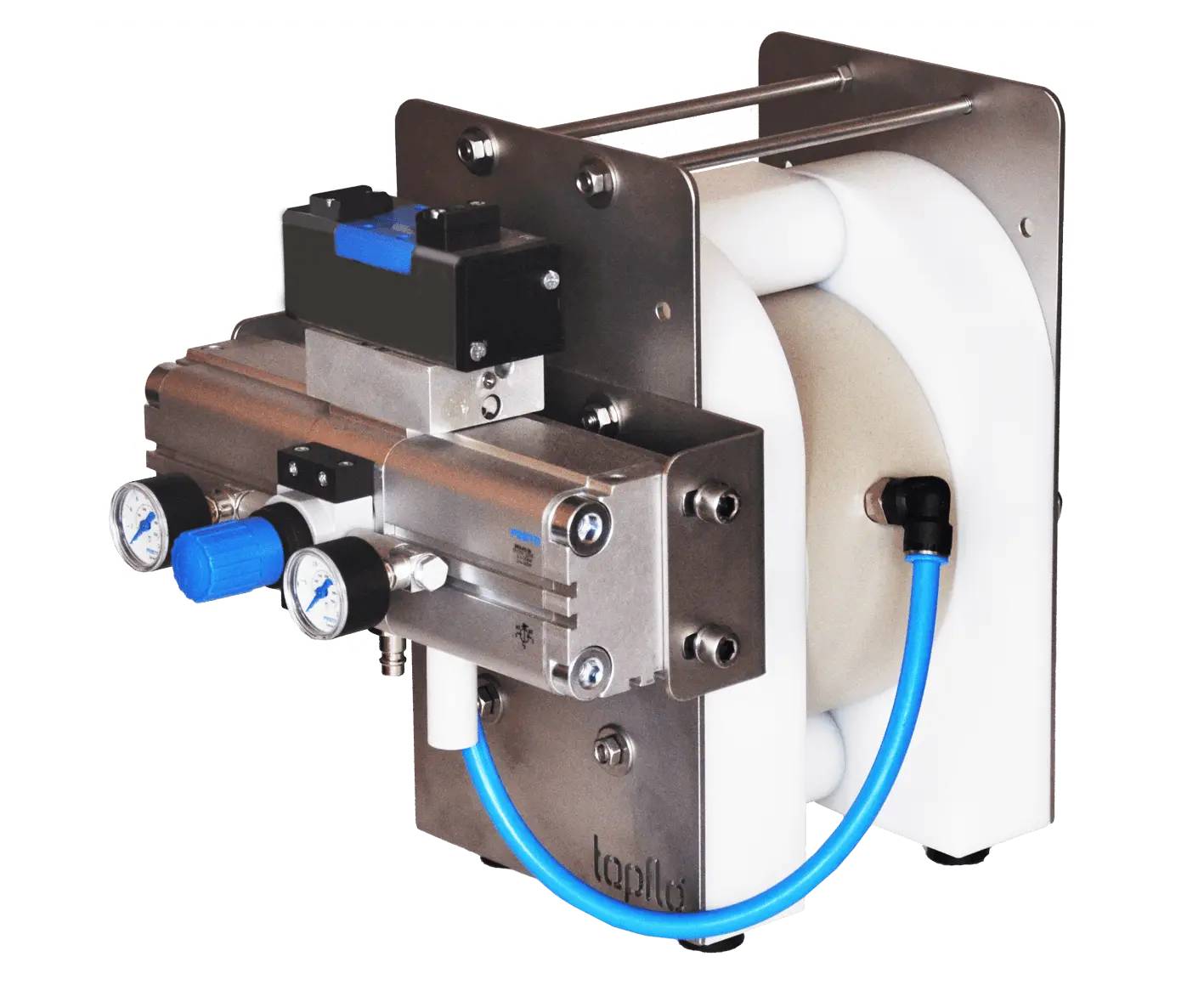

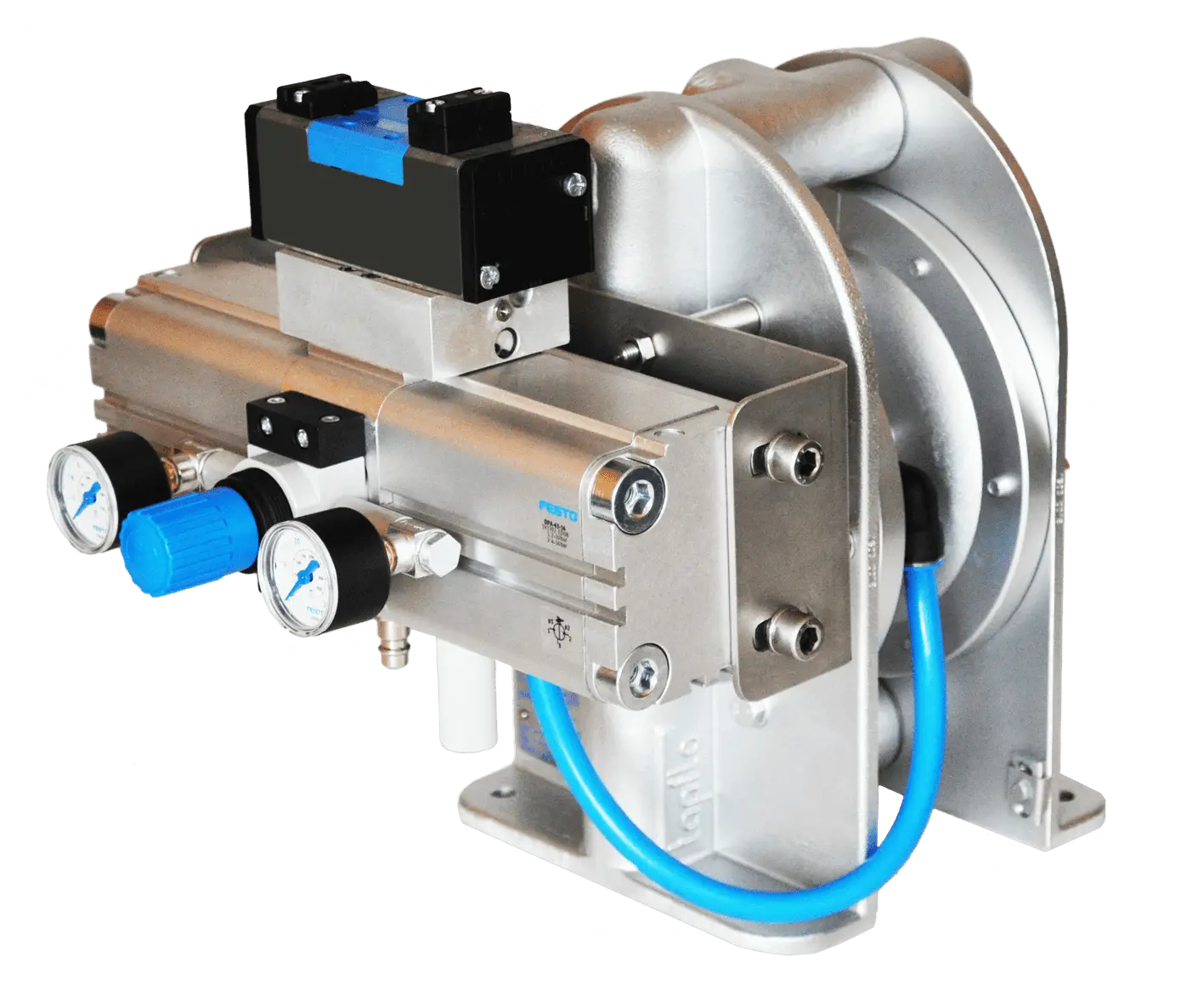

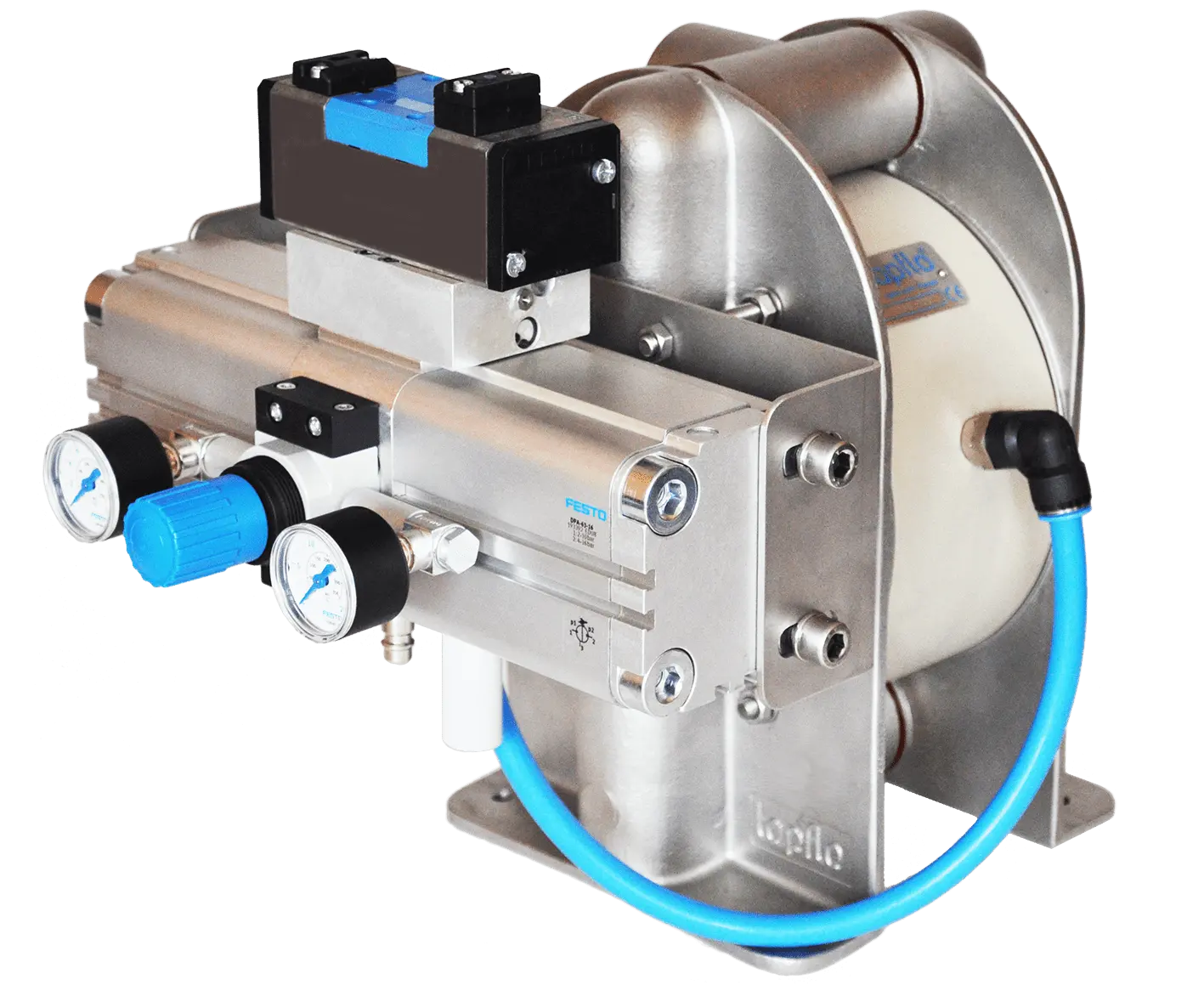

The Tapflo pump station for filter press feeding is a very compact unit that can be mounted directly to the filter press.

The design and function allows the user a straightforward pressing of slurries. Pressure regulator is already mounted to the unit.

An external pressure booster doubles the delivery pressure. For example, with available air pressure of 7 bar, the delivery pressure will be maximum 14 bar.

TF pumps are based on standard Tapflo AODD pump design

- PE & PTFE: TF 50 | TF 100 | TF 200 | TF 400

- Metal pumps: TF 70 | TF 120 | TF 220 | TF 420

Typical applications

- Chemical industry

- Surface treatment

- Water treatment

- Pulp and paper industry

- Hygienic applications

- Mechanical industry

- Paint, print and varnish industry

FEATURES & BENEFITS

- Can run dry

- Self priming

- High pressure transmission up to 1:2

- Few parts – easy to maintain

- Long service life

- Reliable and compact