Specifications

| Max. viscosity | ❮ 100 cP |

| Capacity | ❮ 150 m3/h |

| Pressure | ❮ 50 mlc |

| Impeller | Open + vacuum impeller |

| Materials | Wetted parts: 1.4404 |

| Connections | 3" / DN80 to 6" / DN150 |

| Connections | Couplings: DIN11851, DIN11864-1, SMS1145 Flanges: EN1092-1, DIN11864-2, ANSI Tri-Clamps: ISO2852, DIN32676, DIN11864-3 |

| Shaft sealing | Lubricated single or double oil seal on shaft sleeve |

| Sealing materials | NBR |

| Elastomers | EPDM or Viton |

| Surface roughness | Standard ❮ 0,8 micron |

| Motor options | Standard: IEC, IE3, B3/B5, IP55, isolcl. F, PTC Optional: IE4, low noise |

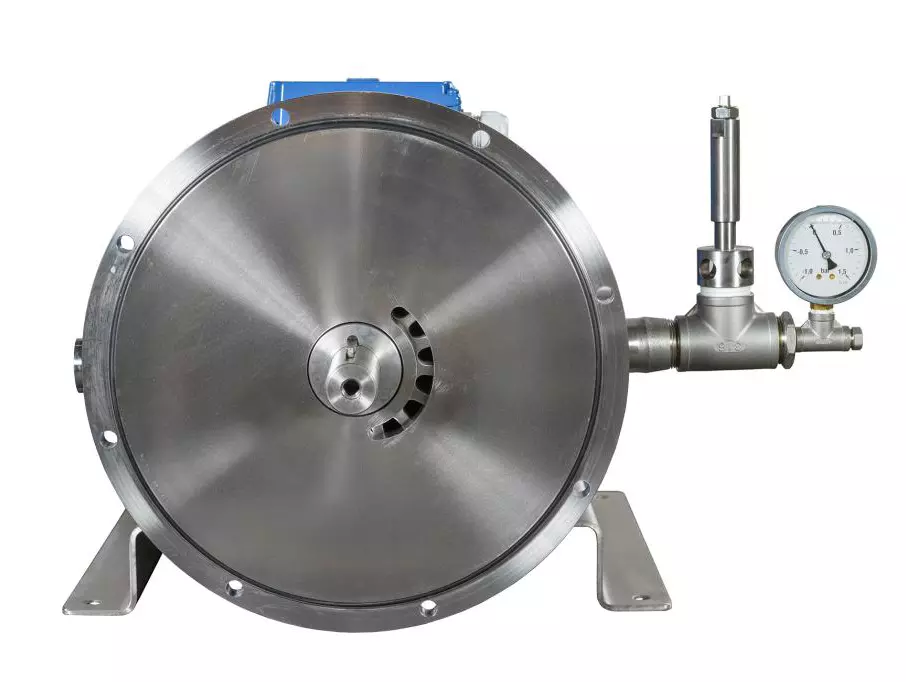

PUMPS FOR FOAMING SLURRIES

WHAT ARE PSVP PUMPS FOR FOAMING SLURRIES FOR? PSVP Pumps are specifically designed for pumping foaming slurries in the starch production process. The PSVP Pump is fitted with a special inlet with guide blades which facilitates the transportation of the slurry which is entrained with gases or foam into the pump casing. The fluid is de-aerated or defoamed in its defoaming compartment before being evacuated. If the fluid also contains fibres then a spiral screw can be fitted on to the eye of the impeller. A special internal contraction allows the transportation of slurries containing air or foam. First, the liquid is de-aired and defoamed in the so-called defoaming compartment. Subsequently, the liquid enters the pump casing via guide-blades where it is pumped away. If the liquid contains fibres as well as foam, a spiral screw can be fitted onto the product impeller Depending on application requirements the pump can be fitted with the following options:

- Spiral Screw

- Single or Double Mechanical Seal with Grease Lubrication

- Vacuum Nozzle

- Vacuum & Pressure Gauges

- Drain Connection