Technical Data

| SHAFT SEAL TYPE: | Sealless Magnetic drive |

| DESIGN: | EN 22858; ISO 2858 |

| STANDART: | ISO 5199 |

| CASING MATERIALS: | PFA lined - PVDF lined – PP Lined |

| CASING PARTITION: | Radially split |

| CASING: | Volute Casing |

| IMPELLER MATERIAL: | PFA lined - PVDF lined – PP Lined |

| TYPE OF IMPELLER: | Closed |

| TYPE OF INSTALLATION: | UTN-L : Long-Coupled UTN-BL : Close-Coupled |

| PULL-OUT DESIGN: | UTN-L : Back pull-out |

| HEATABLE: | No |

| TYPE OF CONNECTIONS: | Flanged |

| FLANGE CONNECTIONS: | UNI 1092-1/ISO 7005-1 PN 16, type B asolate ANSI 150 |

| SUCTION CHARACTERISTICS: | Non-priming |

| TYPE OF LUBRICATION: | UTN-L : Grease |

| DRIVE FREQUENCY: | 50 Hz / 60 Hz |

| TYPE OF DRIVE: | Electric motor |

| MAXIMUM RATED PRESSURE @20°C: | PN 16 |

| MAX. PERMISSIBLE FLUID TEMPERATURE: | PP: - 10°C -> -> +70°C PVDF : -30°C -> +100°C PFA: - 50°C -> +140°C* |

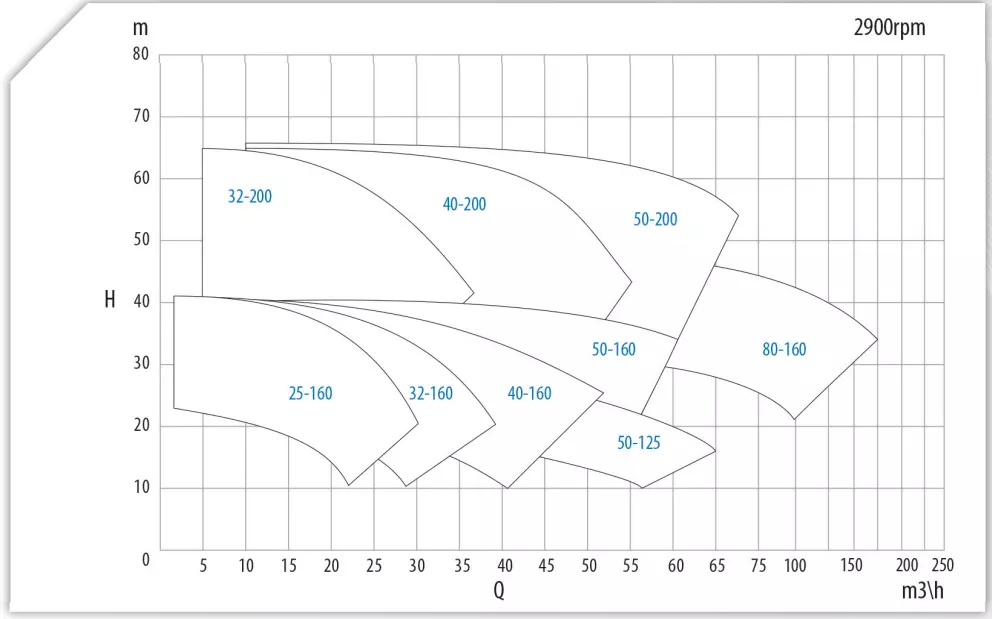

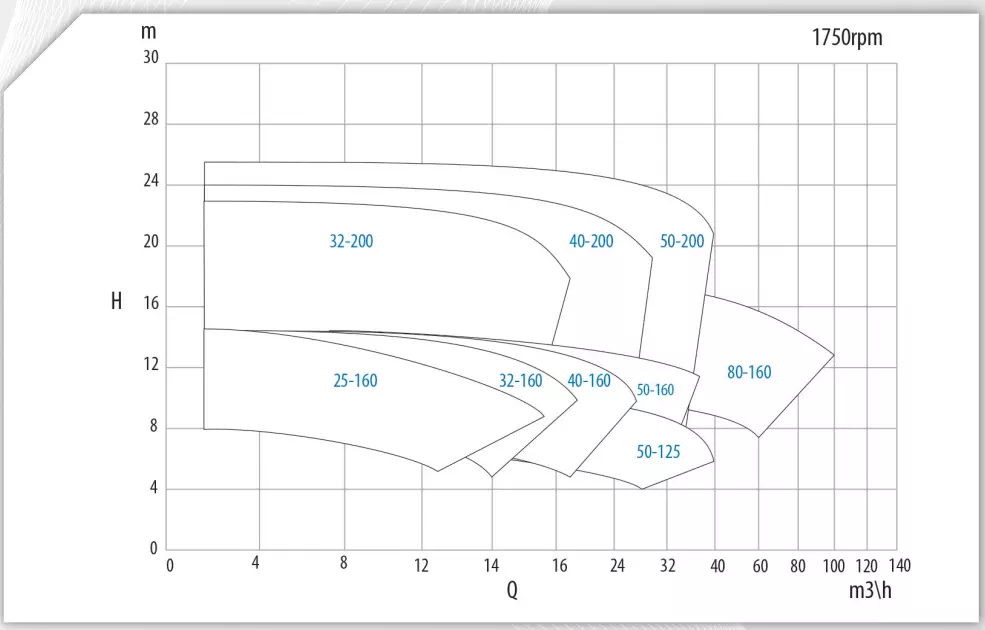

| MAXIMUM HEAD @ 2900 RPM: | 70m |

| MAXIMUM FLOW RATE @ 2900 RPM: | 75 m3/h |

| ALLOWABLE MEDIUM VISCOSITY RANGE: | 1cSt - 100cSt |

| MAXIMUM DRIVE RATING: | UTN-BL: 1.1 kW (motor size 80)-> 18.5 kW (motor size 160) UTN-L: 0.75 kW (motor size 80)-> 37 kW (motor size 200) |

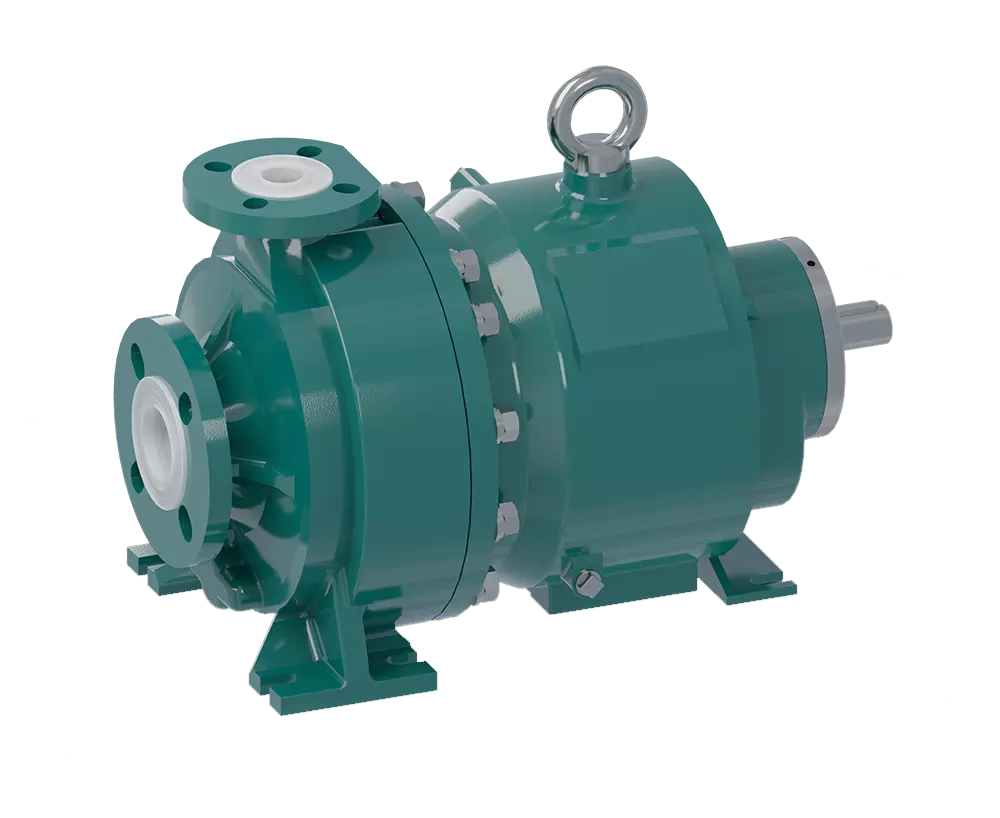

Lined Magnetic Drive Process Centrifugal Pumps

Plastic and Fluoroplastic Lined Magnetic drive Horizontal Process Centrifugal pumps

Lining: PP (Polypropylene), PVDF (Polyvinylidene fluoride), PFA (Perfluoroalkoxy) End-suction - Long Coupled (UTN-L) and Close Coupled (UTN-BL) execution

Mag drive concept

The synchronous drive configuration is based on an outer magnet ring assembly built to magnetically couple with an inner magnet ring assembly.

These two magnet rings are locked together by the flux of attracting magnet poles flowing through the containment isolation shell.

Versatility: suitable for handling corrosive, aggressive and hazardous liquids (low viscosity, clean or slightly contaminated) in the chemical, petrochemical and Pharma industries, where the need of high safety standards is the first requirement

Reliability: the pump is equipped with reliable oil lubricated bearing bracket, especially developed to be suitable even under heavy duty service.

Design: UTN range share the same hydraulic design with the UCL series (mechanical seal pumps) which have been developed focusing on the needs of the chemical industry.

Typical applications

- Petrochemical processing

- Fertilizer processing

- Basic chemical processing

- Air treatment

- Fine chemical processing

- Detergents processing

- Fibra processing

- Active pharmaceutical ingredients