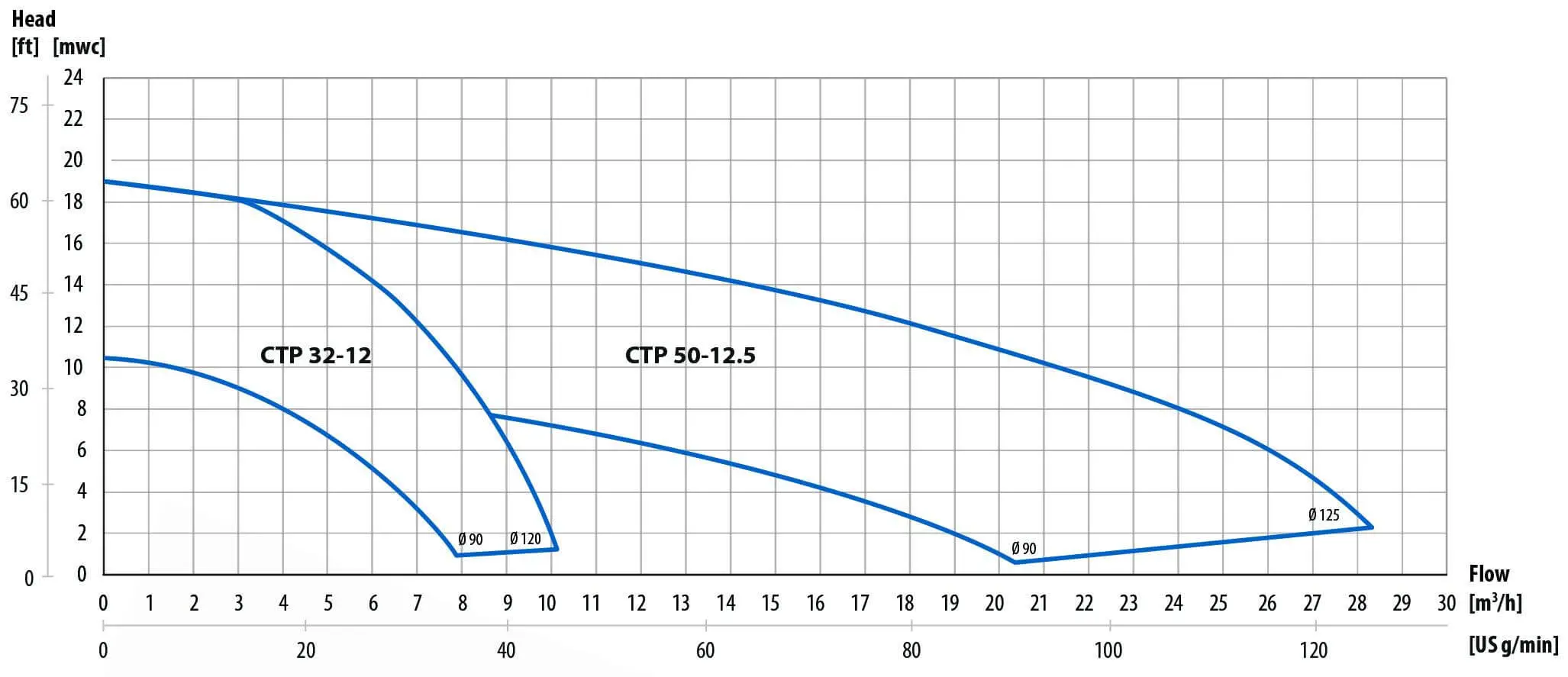

Technical data

| Model | Motor power , kW | Outlet dimension (male BSP) |

| CTP 32-12.5 | 0.75-1.1 | 1 1/4" / 1" |

| CTP 50-12.5 | 3-4 | 2" / 1 1/2" |

Materials, data and limits

| Casing | PP-GF (30%) or PVDF |

| Back casing, Impeller | PP or PVDF |

| Lantern (not wetted) | PP |

| Mechanical seal | Rotating part: SiC or Graphite, Stationary part: SiC, Spring: Hastelloy C-2761 |

| O-rings | EPDM, FEP/FKM, FKM |

| Shaft | AISI 316L stainless steel (standard) or Hastelloy® C-276 |

| Motor* | IEC standard, 3-phase, 2-pole, IP55 |

| Pressure rating | PP: PN6 at 20 °C; PN2 at 70 °C PVDF: PN6 at 20 °C; PN2 at 90 °C |

| Temperature | PP: 0 °C - 70 °C; PVDF: 0 °C - 90 °C |

| Viscosity | max ~200 cSt |

| Particles | max diameter is Ø 3 mm and 10% in concentration |

| 1Hastelloy® C is a registered trademark of Haynes International, Inc. *other motor options available on request |

|

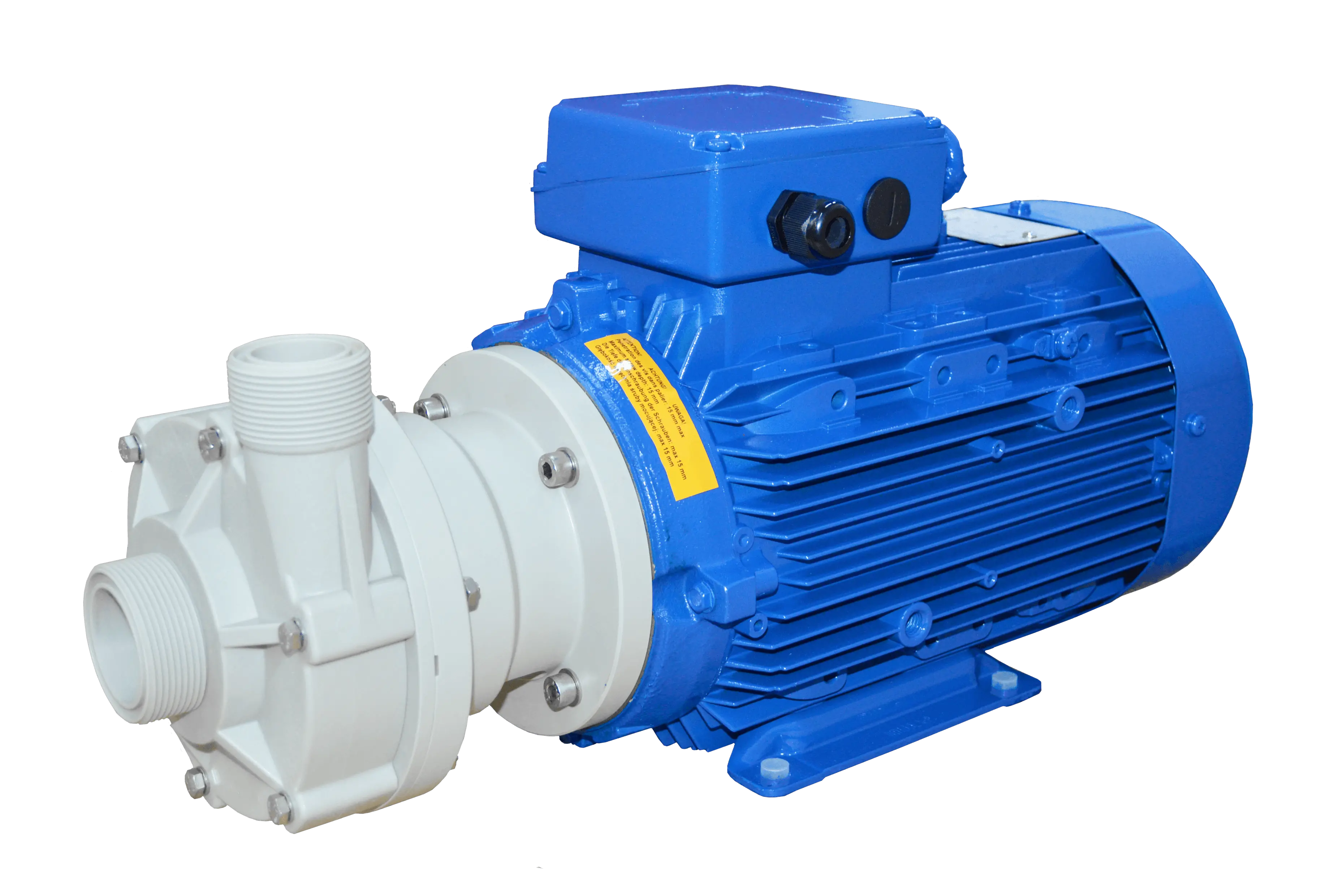

Compact and reliable mechanically realed pump

The CTP pumps are semi open single stage centrifugal pumps. Since there are no metal parts on the liquid side, the pumps are ideal for chemicals transfer and circulation in surface treatment industries.

CTP is a compact and reliable mechanically sealed centrifugal pump made in PP and PVDF. It is the right solution for liquids containing solid particles.

Features & Benefits

- Mechanical seal

Spring on air side of the pump; different material executions for various applications - Semi open impeller

Allows pumping liquids with particles - No metal parts in contact with the liquid

- PP & PVDF wetted materials

can handle highly corrosive liquids - Few parts

low maintenance, easy to handle - Optional flange and hose connections

Typical APPLICATIONS

- Transfer of chemicals

- Surface treatment

- Food and beverage

- Water treatment

- Chemical manufacture

- Demineralization

- Photo processing

- Liquid crystal manufacture