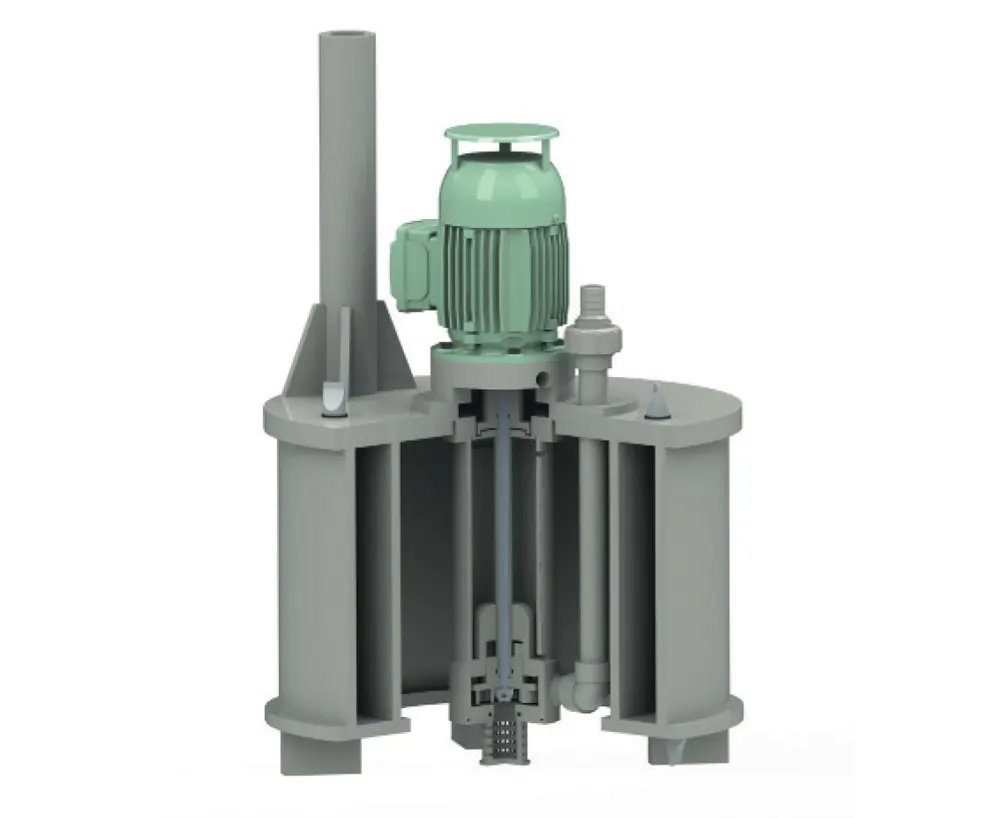

Working principle

The suction pipe can be connected directly through the tank wall (A) or it can be in the form of a siphon pipe (B), as shown in the drawing.

In the event of the close valve on the discharge pipe, the overflow pipe (C) relieves pressure by conducting the liquid back into the tank.

OUT OF TANK MODEL BB

This pump offers the same advantages as the previous models but is designed for ‘out of tank’ use. Main advantage is that it can be used if there is insufficient space inside the tank. The suction pipe can be connected to the bottom ofde process tank of it can suck over the tank wall. Additional advantage is that can suck from a second circuit by tapping the suction pipe, for example, for pre-coating or flushing operations

DRY RUN RESISTANT

Although the pump is “dry-mounted” it can be run dry without damage as there is no seal and no bearing in the pump housing. An advantage when handling adrasive or crystallizing liquids.

SPACE EFFECTIVE

Additional advantage are that it can be used where there is insufficient space inside the tank, and that it can pump over a second circuit by tapping the suction pipe, for example, for pre-coating or flushing operations.

CORROSION RESISTANT

There is no metal to liquid contact; wetted parts of the pump can be PP or PVDF according to suitability for the intended use. Gaskets of EPDM are standard and optional are Viton or PTFE-encapsulated O-rings.