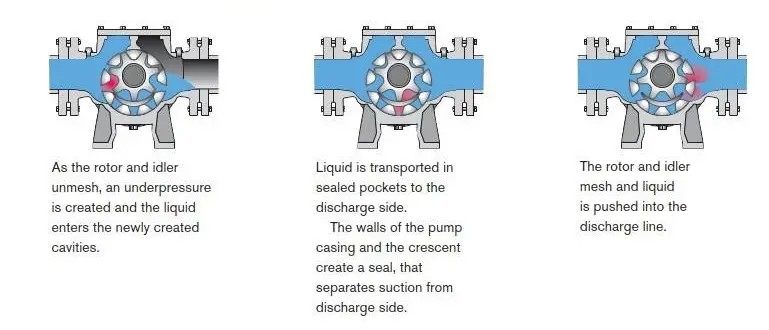

The Top Gear pump design is based on an internal idler gear rotating inside of a larger rotor. Internal gear pumps are robust, give an even flow, handle both low and high viscosity products, are capable of high pressure and are self-priming.

TopGear G-series

TopGear G-series are available in cast iron with inline port connections. Baseplate-mounted. Heating and cooling jackets are available for pump cover and around shaft seal. Built-on single or double safety relief valves are available.

Material of components

| Component |

Model: Material |

| Casing |

Cast iron |

| Idler and rotor |

Nodular iron, Stainless steel |

TopGear H-series

TopGear H-series is available in nine different sizes. The modular design gives a wide range of possibilities. Shaft seal options include single and double mechanical seals as well as packed gland and cartridge seal. Baseplate-mounted. Heating and cooling jackets are available for pump cover and around shaft seal. Single or double safety relief valves are available built-on. Connections from 32 to 150 mm.

Material of components

| Component |

Model: Material |

| Casing |

Stainless steel, Cast steel,

Nodular iron |

| Idler and rotor |

Nodular iron, Stainless steel |

TopGear L-series

TopGear L-series is available in six different sizes. Shaft seal options include mechanical seals, packed gland and double flushed PTFE lipseals. Flange-mounted or bracket for foot-mounting, the TG L pedestal fits to IEC-flanged motors. Safety relief valves are available built-on or separately. Connection sizes from 1" to 1.1/2".

Material of components

| Component |

Model: Material |

| Casing |

Nodular cast iron

One size in stainless steel |

| Idler and rotor |

Steel |

Jacket options

Heating and cooling jackets guarantee the performance of the pump in a start-up or a shut-down procedure. They also provide the pump with the best condition for the seals during operation. Different options: thermal oil, steam or electrical heating.

Safety relief valve options

Built-on safety relief valves protect the pump, as well as other equipment in the system, from overpressure. When the pump is used bidirectionally, a double safety relief valve is provided.

Shaft seal options

Shaft seal options include packed gland, single and double mechanical

seals (to EN 12756), lip seals and cartridge seals.