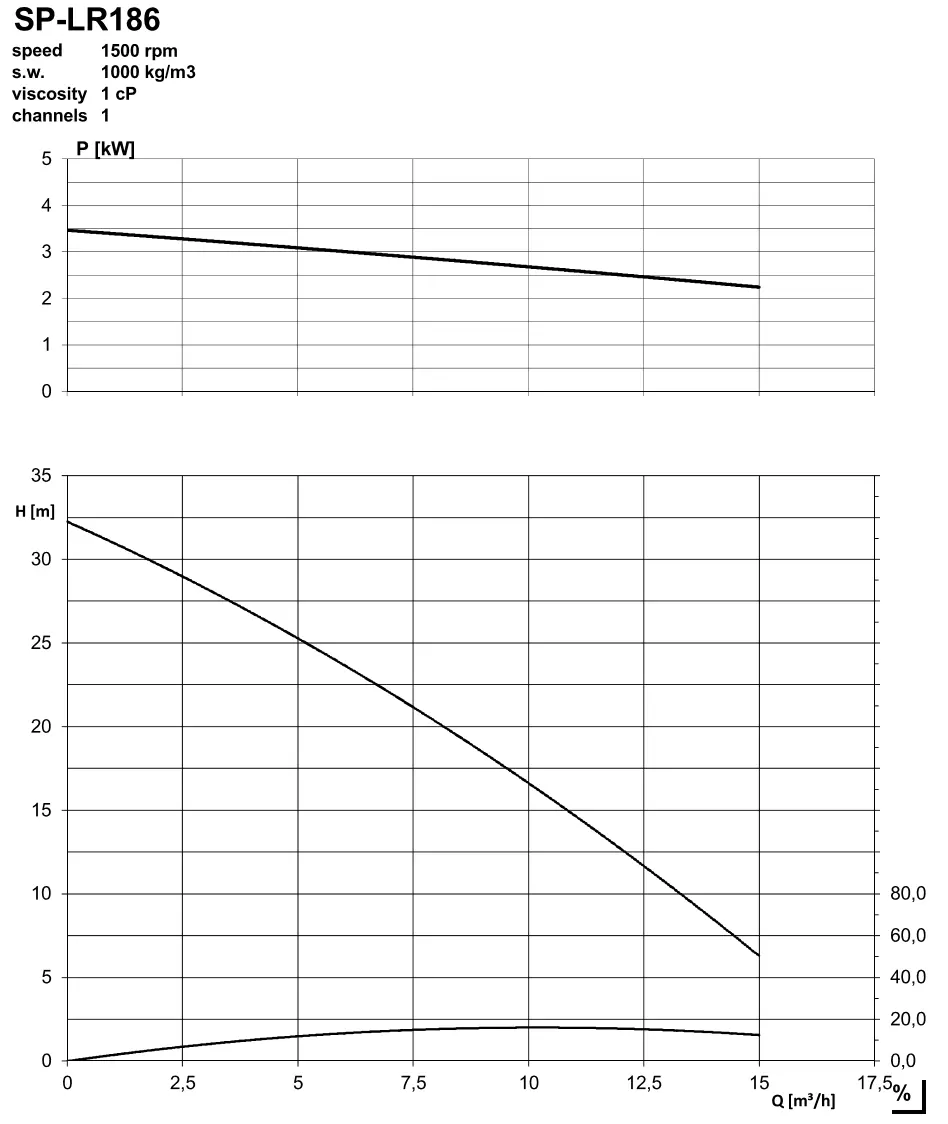

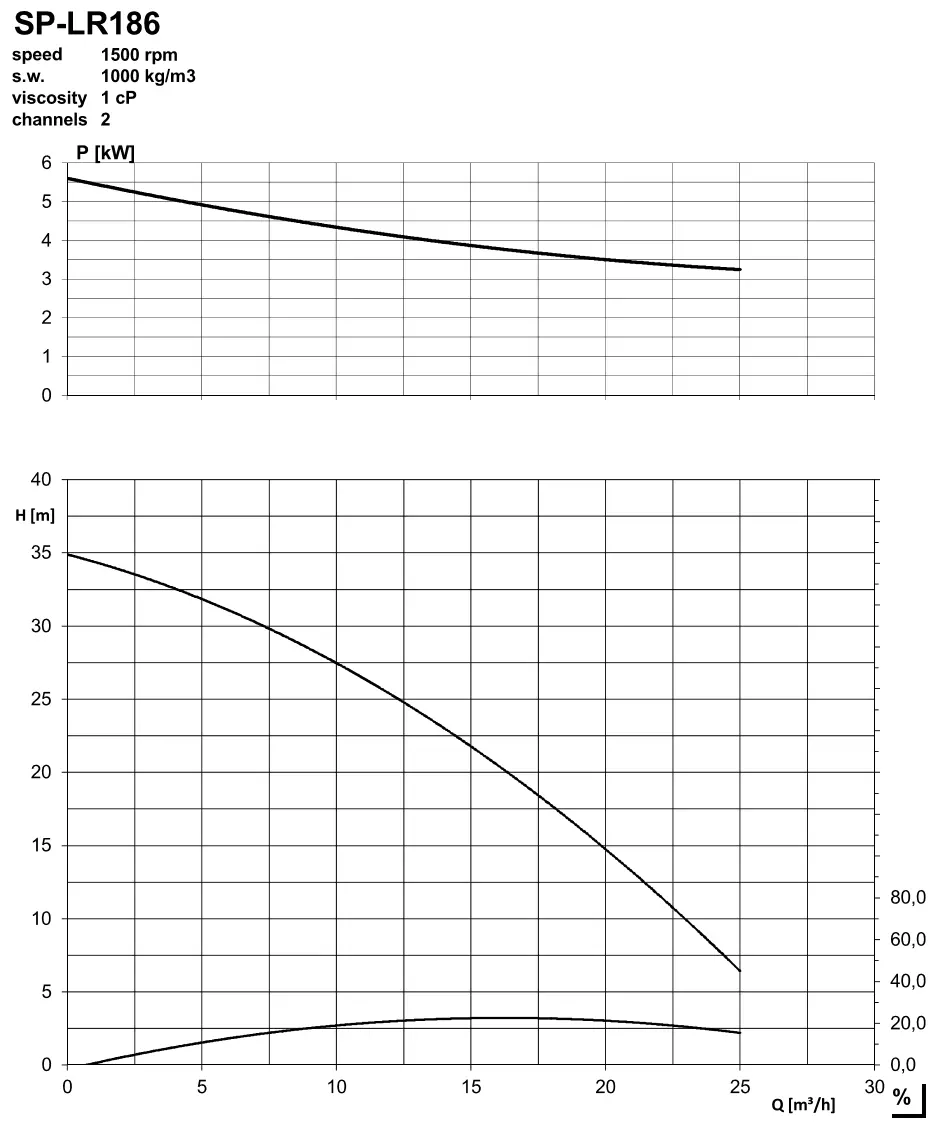

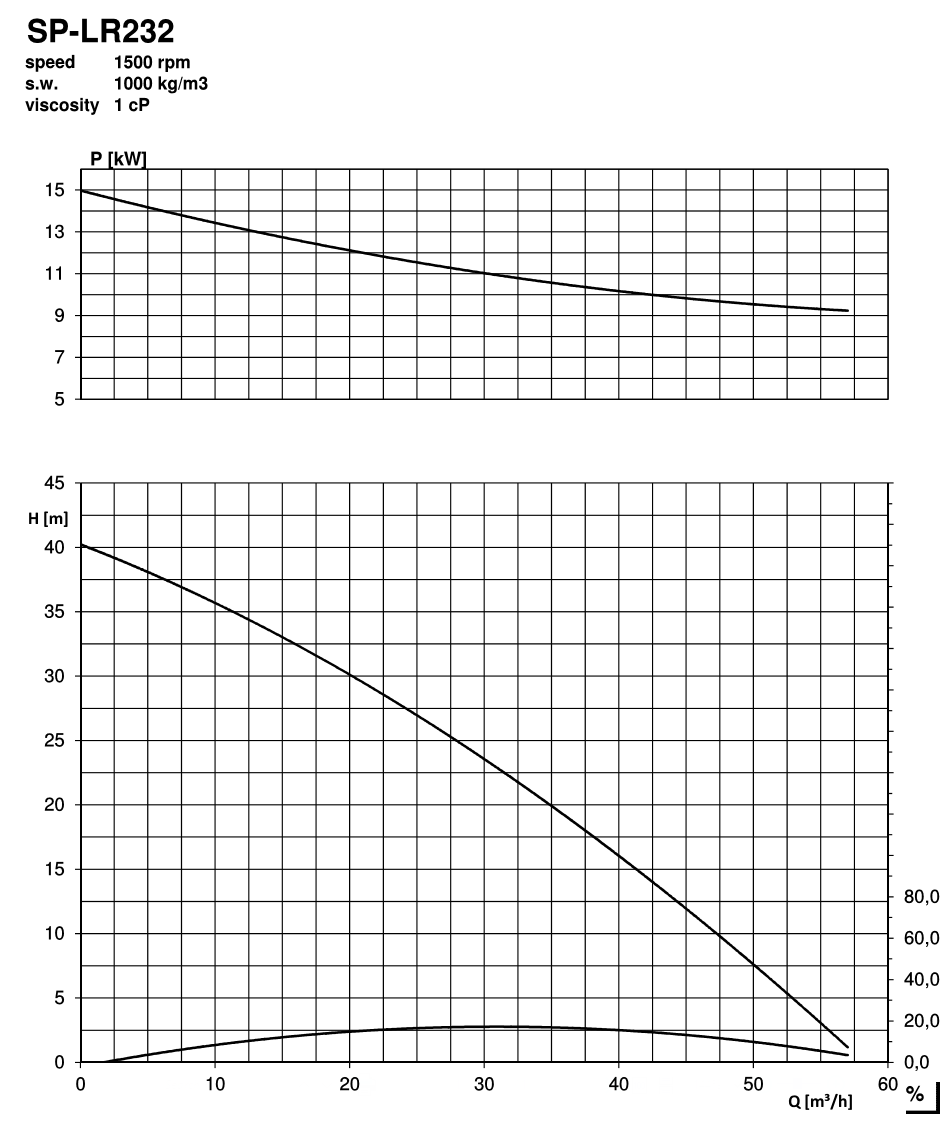

DATA & LIMITS

| Max Capacity | 60 m3/hr |

| Max Pressure | 4 Bar |

| Max Viscosity | 500 cPs |

| Max Temperature | 140ºC |

| Max Suction Lift | 6-8 mm |

| Connections | 2” – 2½” |

| Connection Types | Couplings: DIN11851, DIN11864-1, SMS1145 Flanges: EN1092-1, DIN11864-2, ANSI Tri-Clamps: ISO2852, DIN32676, DIN11864-3 BSP & NPT threaded |

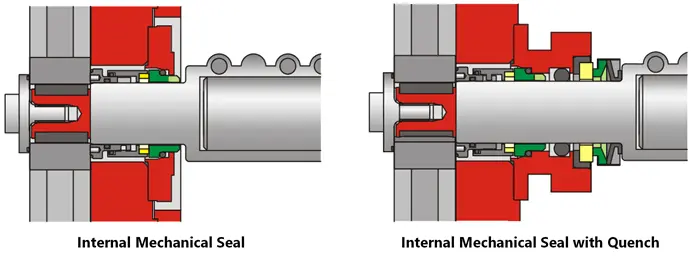

| Shaft Sealing | Single, double quench/flush, Inner and outer, EHEDG. according to DIN24960 |

| Sealing Materials | carbonl/CrM, carbon/SiC, SiC/SiC, Tc/Tc |

| Elastomer Materials | EPDM, Viton, NBR, Teflon, KALREZ, e.g. according to FDA |

| Wetted Parts | AISI 316L (AISI 316L Mo+Ni or Hastelloy CX2MW N26022 upon request) |

| Surface Roughness | ‹0.8 Micron (Std), ‹0.5 upon request (Mechanical & Electro-Polished) |

| Drives | Standard: IEC, IE2, B3/B5, IP55, isol cl. F, PTC Optional: IE3, ATEX, noise reduction |

Sanitary Self Priming Liquid Ring Pump

The SP-LR Sanitary Self Priming Liquid Ring Pump has been produced specifically for hygienic and sanitary applications within the food, chemical and pharmaceutical industries for liquids which contain air or gases. The series is fully compliant with all relevant standards and has been designed with a heavy emphasis on compactness, robustness, cleanability & low maintenance costs. The open impeller, which is dry mounted, ensures optimal cleaning of the shaft and sealing chamber and the applied O-Ring minimises liquid contact whilst ensuring optimal cleaning of the contact faces of the seal.

All pumps within this range are suitable for being CIP cleaned. The range currently consists of 2 pump sizes, with 4 more in development. Capacities available are up to 60 m³/hr & 4 Bar max deliverable pressure with connection sizing ranging from 2” to 2½” in a variety of types. The pump is entirely machined from cast Stainless Steel AISI 316L with a surface roughness

Upon request, the pumps can also be delivered in Supra SS 316L and Hastelloy C22. Various O-Ring and Mechanical Seal variants can also be applied to ensure that these pumps meet the requirements of almost any application.

As standard, the range is supplied in a close coupled configuration encased in a hygienic shroud with adjustable feet and the impeller is mounted by a balanced stainless steel stub shaft. Upon request they can also be provided in a bearing housing execution for high temperature applications or fitting with hydraulic motors.

Heating jackets & casing drains can also be fitted if required. Motors can be supplied in all efficiency, isolation, protection and voltage classes and they are also available in ATEX compliant executions and fitted with noise reduction measures.