Dimensions

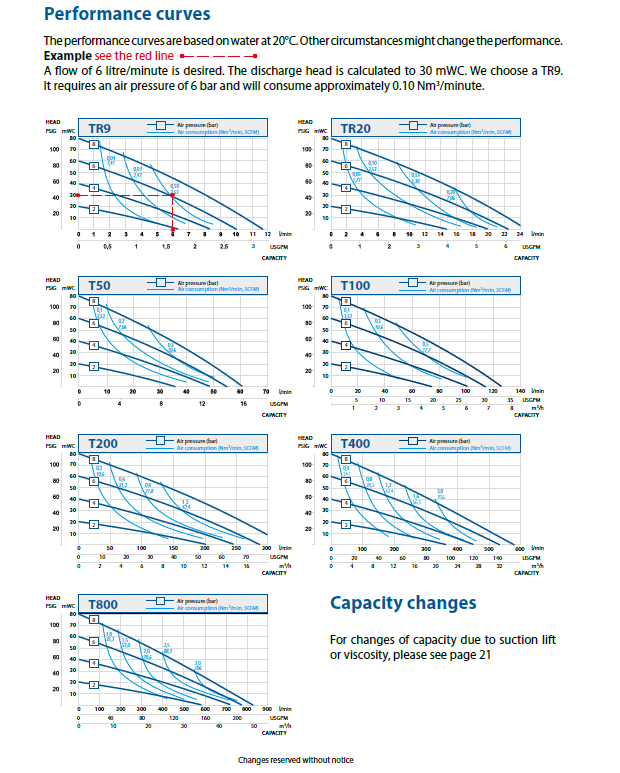

| Model | Max capacity (l/min) |

Connections BSP inv. |

| TR09 | 11 | 1/4" |

| TR20 | 24 | 3/8" |

| T50 | 60 | 1/2" |

| T100 | 125 | 1" |

| T200 | 330 | 1 1/2" |

| T400 | 570 | 2" |

| T800 | 820 | 3" |

Made from polyethylene (PE) or virgin PTFE plastics they are suitable for handling almost any kind of liquid whether it is viscous, chemically aggressive or with solids.

Few components and a simple but ingenious design is peculiar for all Tapflo pumps. It is a compact pump, easy and quick to maintain, keeping your service costs and process down time to a minimum.

Polyethylene (PE) pumps

Polyethylene (PE HD) has a superior wear resistance which is 6 – 7 times better than for polypropylene (PP). This fact makes the pump suitable for handling abrasive slurries etc. PE is resistant to most kind of aggressive chemicals such as concentrated acids and alkalis. Maximum liquid temperature is 70°C.

PTFE pumps

PTFE (virgin polytetrafluorethylene) is a thermoplastic polymer with superior chemical resistance. The PTFE pump will handle even the most aggressive acids, for instance concentrated nitric acid. Maximum liquid temperature is up to 100°C.

Specifications

- Max capacity: 820 l/min

- Max discharge pressure: 8 bar

- Material: PE or PTFE

- ATEX

Typical applications

- Chemistry: acids, alkalis, alcohol, solvents, latex, emulsions

- Food: CIP fluid, flavouring, pigments

- Pulp, Paper: glue, slurries, adhesives, dispersions, resins, sodium silicate, titanium oxide

- Surface conditioning: electroplating baths, various acids, solvents, anodic sludge, varnish, enamels

- Water treatment: sludge handling, filter press applications, neutralization and flocculants

- Electronics: carrier fluids, ultra pure liquids, electroplating solutions, mercury, solvents

- Print, paint: glue, additives, varnish, ink, paint, latex, acid, resins, pigment