One of the biggest challenges when using positive displacement pumps are the pressure variations on the discharge side.

Depending on the functional principle, these effects are larger or smaller, but they are always present.

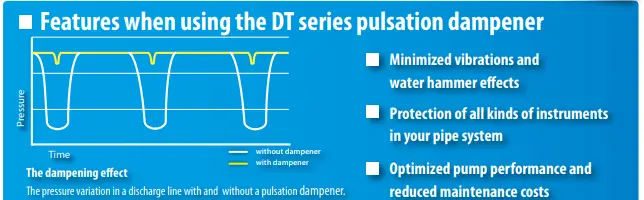

This often poses a challenge for end-users. These pulsations can not only be harmful to the pumped product but they also place a particularly high load on the installed equipment.

Depending on the intensity, this can lead to hammering noises or vibrating pipes and hoses.

These pulsations are particularly harmful to any downstream sensor technology, such as pressure or flow sensors. It also makes a repeatable dosing and filling process complicated.

DT Tapflo active pulsation damper

With the DT pulsation dampener, we can offer suitable solutions to the above-mentioned problems.

Optimized for use with Tapflo air-operated diaphragm pumps, these dampeners are the most effective and easiest way to eliminate pressure variations on the pressure side of the pump.

Due to the "inline" design, the liquid can be pumped without additional pressure losses, shear impacts and product impairments. This is a decisive advantage, especially for share sensitive liquids, viscous liquids or liquids with a high concentration of solids. It should also be noted that reduced pressure fluctuations reduce the pressure losses in the pipeline and thus the delivery rate is increased.

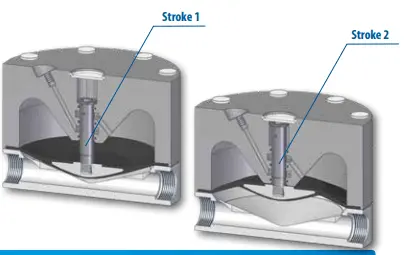

"Active pulsation dampener" - The Tapflo pulsation dampener actively collaborates with the pulsating flow of the pumped liquid. Due to the supply of compressed air, which is taken from the pump air inlet, there is the same pressure in the pulsation dampener as in the pump. If the pressure between the pump strokes in the pipeline drops, the dampener provides additional pressure on the pumped fluid. Which reduces or prevents the pulsation.

Furthermore, the pulsation dampener adjusts itself by default, to changing delivery conditions or pumped media.

Very high priority is also put on the protection of expensive and fragile instruments installed in modern production and supply pipelines. By using a Tapflo pulsation dampener, the use of a flow meter and its correct functioning is often made possible.

Materials and applications

The maintenance-free pulsation dampener is manufactured by Tapflo in plastic PE & PTFE as well as in stainless steel, polished stainless steel and aluminium. The high-performance diaphragms made of PTFE, EPDM, NBR and other are characterized by a particularly long service life due to their sandwich design and integrated metal core. For particularly demanding applications, the pulsation dampener can also be equipped with a double diaphragm system with a barrier chamber to monitor the diaphragm state.

The pulsation dampeners are also available in sanitary and high-pressure executions.

The fulfilment of the ATEX Directive 2014/34/UE completes the application range of the pulsation dampener and extends it to almost all application areas of the industry.

Food, pharmaceuticals and cosmetics

With our hygienic series, our Tapflo pulsation dampeners find their application in many areas of the food, cosmetics and pharmaceutical industries. Of course we meet all required European as well as international standards like EN 10204, FDA, EC 1935/2004, EC10/2011 and USP VI.

The dead-space-free design of our pulsation dampener is easy to clean with CIP & SIP and self-draining if installed vertically. This does not leave room for product residues and bacteria to grow. The dampener can be equipped with a wide range of sanitary and aseptic connections like tri-clamp, DIN 11851 or DIN 11864 to name a few.

Chemistry, surface technology, wastewater treatment, ceramics

Aggressive chemicals, thick pastes or sensitive filtration processes. Safe pumping, reduced spray performance, consistent throughput and coating are just a few of the arguments in favour of a Tapflo pulsation dampener.

Paints, printing and packaging industry

The constant and reliable supply under all operating conditions of paints, varnishes, coating agents and pre-treatments can be simplified and cost-optimized here. Last but not least, this often speeds up the process and saves time and product costs.

Use for all positive displacement pumps possible!

The Tapflo pulsation dampeners are not only used for the own manufactured diaphragm pumps, they can be also installed in existing systems with pumps from different suppliers.

Likewise, electrically operated pumps with strong pulsations such as peristaltic pumps, piston pumps and all other pulsating pumps, can be upgraded with the pulsation dampener

Plug and play

Particularly practical and space-saving are the integrated pulsation dampeners of the "Built on" and TK series. In this case, the pulsation dampener is already installed on the pump.