Dimensions

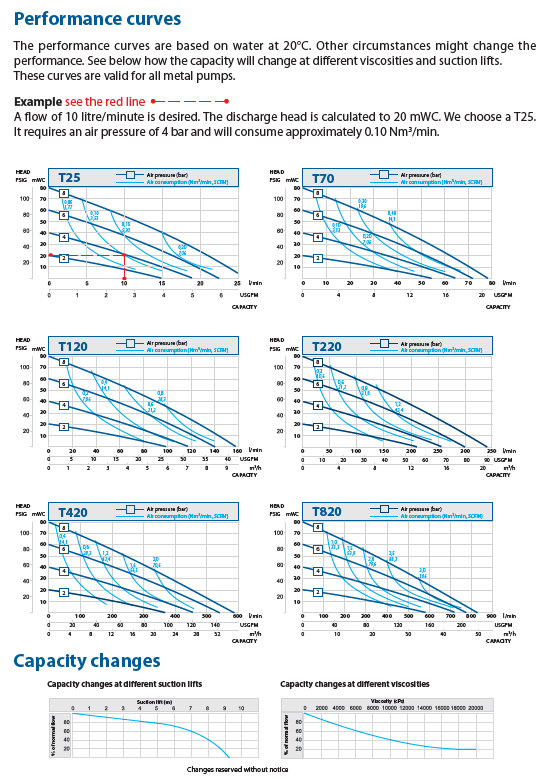

| Model | Max capacity (l/min) |

Connections BSP inv. |

| T25 | 26 | 1/2" |

| T70 | 78 | 3/4" |

| T120 | 158 | 1" |

| T220 | 330 | 1 1/2" |

| T420 | 570 | 2" |

| T820 | 820 | 3" |

The compact, smooth and simple design is common for this series. Materials available are aluminium, cast iron, stainless steel and PTFE coated aluminium.

You will discover the ingenious simplicity when you maintain the pump. We use approximately 70% fewer parts than our competitors use to build similar sized pumps.

Aluminium and cast iron pumps

For transfer of pH-neutral fluids, both thin, thick, solid-laden or abrasive. Pumps made of aluminium and cast iron can be found in a wide range of applications, including workshop and paint industries, purification plants, to mention just a few.

AISI 316 stainless steel pumps

Made in lost wax cast method, ensuring great accuracy and finish. The stainless steel pumps combine great mechanical strength with good chemical resistance. AISI 316 is resistant to aggressive liquids like nitric acid and sodium hydroxide. The centre unit, which is not in contact with liquid, is made from polypropylene (PP) as standard (other materials upon request).

ATEX certified pumps

All metal pumps are available in explosion proof ATEXmarked version. They are supplied with earth connection and conductive materials; conductive centre section (on AISI 316 pump), diaphragms in PTFE (conductive back) or EPDM (conductive).

Typical applications

- Workshop: Oil, fat, solvents, water, cooling fluid, lubricants

- Print & paint: Glue, additives, varnish, ink, paint, latex, acid, resins, pigments

- Mining & construction: Adhesives, sump, dewatering, coal sludge, pastes

- Ceramic industry: Abrasives, glaze, water, enamels, clay

- Chemistry: Acids, alkalis, alcohol, solvents, latex, emulsions